Report Overview

Antimony Refining Technologies Market Highlights

Antimony Refining Technologies Market Size

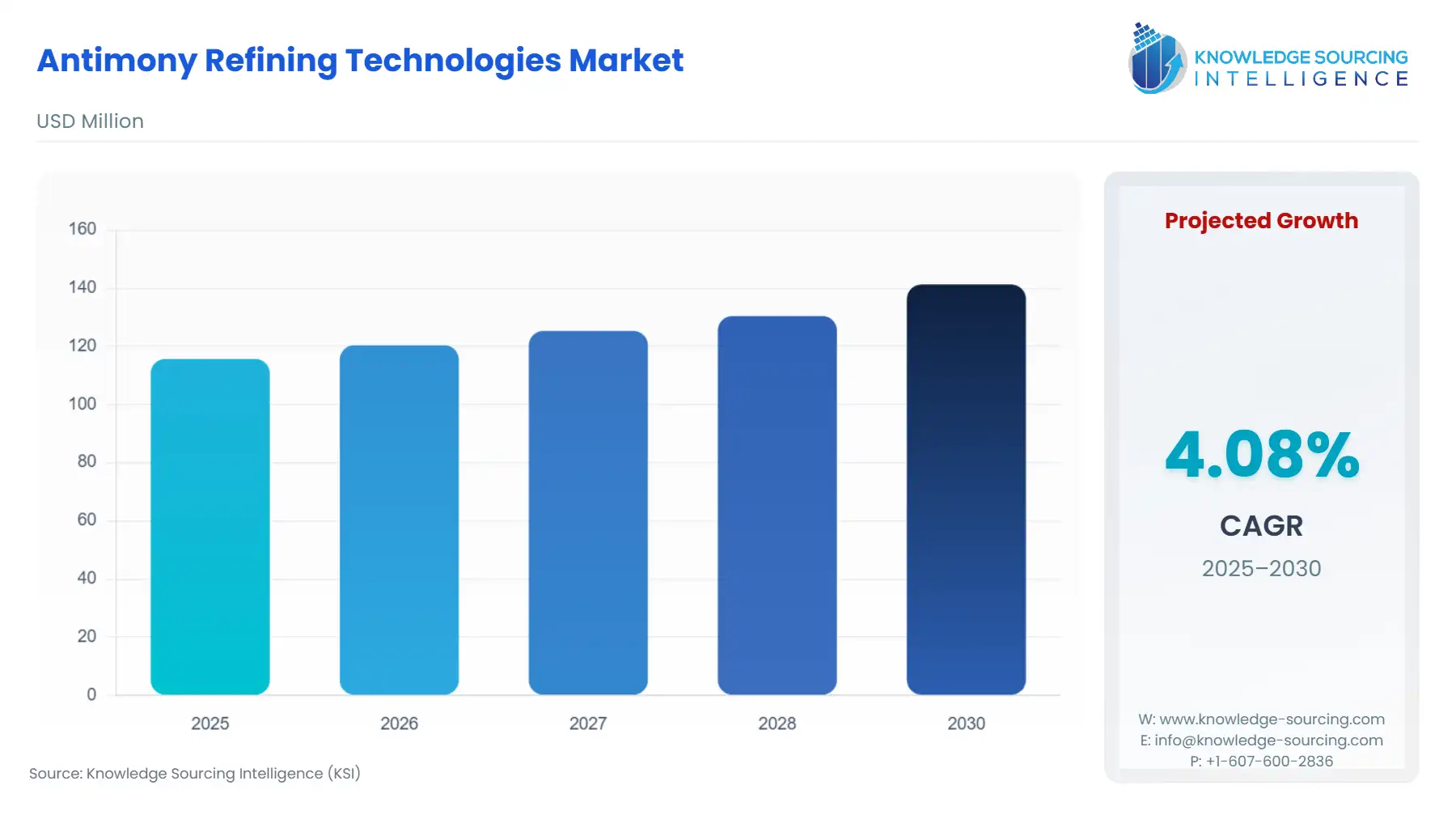

The Antimony Refining Technologies Market is projected to expand at a CAGR of 4.08%, attaining USD 141.312 million in 2030 from USD 115.684 million in 2025.

The international antimony processing technology market continues to grow steadily as the industrial use of high quality antimony in various fields is constantly growing.

Antimony is a necessary material for flame retardants, lead-acid batteries, alloys and special chemicals, which leads to the development of more efficient processing techniques in order to meet quality and legal standards. Manufacturers are increasingly focusing on the production of refined antimony for industrial application, which meets strict specifications and constant performance and safety control. The way of processing changes thanks to new pyrometallurgical, hydrometallurgical and other electrolytic methods, allowing recovery of technological efficiencies and energy savings and purity of the product. As this means that the refiners can up-grade in various refining benefits the use of low-grade ores and good data for quality to be obtained, at the same time offering the necessary use, essential for the electronic and automotive and construction application. Regulations from the ecological and the ecological development influences the market. The manufacturers are encouraged to apply new procedures, which ensure that the ecological impact and minimizing the emissions and the waste of waste. The strategic investments in advanced technology and automation help refiners produce economies of the refined factors, and at the same time reduce and comply with the changed specifications needed for the improved ecological causes.

Antimony Refining Technologies Market Overview & Scope

The Antimony Refining Technologies Market is segmented by:

- Refining Method: Segmentation takes place across pyrometallurgical, hydrometallurgical and electrolytic processes. Pyrometallurgical processes are prominent because this type of refining can be applied to large volumes of antimony ore at high temperatures, giving products in metal and oxide forms. These chemical products are useful for industrial purposes. Pyrometallurgical processes has high recovery yield and are suited for commercial production. The hydrometallurgical and electrolytic methods are being developed into more useful processes because of their accuracy in operation, energy efficiency and the ability of these processes to produce ultra-pure products. This is particularly true for antimony for special purposes.

- Application: Applications include use for flame retardants, lead-acid batteries, alloys etc, chemicals and other industrial use. Flame retardants is a leading segment as antimony compounds improved fire resistance to plastics textiles and electricals. Because of stricter fire regulations and growing industrial needs for these applications, refiners in general have moved to the production of high-purity antimony to give consistent performance of their products.

- End Use: The end uses included in the economics are electronics & electicals, automotive, construction, chemicals & pharmaceuticals, defence & ammunition and other sectors of industry. The demand from the electronics & electricals has been appreciable and is leading in terms of high-purity antimony used in semiconductors, printed circuit boards, flame-retardant plastics, thus assuring product safety, reliability and the ability to meet regulatory standards.

- Region: Geographically, the market is expanding at varying rates depending on the location.

________________________________________

Top Trends Shaping the Antimony Refining Technologies Market

1. Adoption of Advanced Refining Methods

- With the increasing use pyrometallurgical, hydrometallurgical and electrolytic processes by competitors who are working to increase recovery rates, reduce energy consumption and produce an improved standard of antimony, we can expect a gradual improvement in the standard of the products produced and they will find their way into more markets.

2. Focus on Sustainable and Eco-Friendly Operations

- This industry is under a great deal of pressure to increase strain on sustainability, environmental initiatives, through clean production methods. Effluence, recycling of wastes and the use of power effective schemes ought to be in every manufacturers book to reduce carbon footprints. This is necessary to comply with environmental laws, production efficiency and global industrial demand.

________________________________________

Antimony Refining Technologies Market Growth Drivers vs. Challenges:

Drivers:

- Increasing Industrial Demand: This Industry will be boosted by advances in electric are furnaces facilitated by the growing demand from the electronics, automotive, building and construction, and the chemical and allied industries for high-grade antimony used in the manufacture of flame-proof materials, lead and other acids, alloys, etc. Growing industrialisation, coinciding with stricter safety requirements for users, will lead refiners to the paths of least consumption of their resources, which will enable them to supply antimony powders of a specific quality, so that the capacity of the product will not be a problem.

- Technological Advancements in Refining: With the rapid advances of pyrometallurgical or hydrometallurgical, and electrolytic refining processes and technology, recovery rates of antimony will greatly improve, together with the efficiency of use of power and an increased standard of purity of the end product. The application of some of the modern techniques will enable lower values of ores to be treated and wastes to be minimised concurrently satisfying market demands of high quality standards, and the environment. Then, in turn, the use of mechano-technological improvement and optimisation of methods to manufacture on a greater scale without impinging upon good philosophy with regard to human remains in the market for growth and progress, long filled with benefits for mankind.

Challenges:

- Environmental and Regulatory Constraints: Strict environmental regulations on emissions and waste management increase operational costs and complicate the establishment of new refining facilities.

________________________________________

Antimony Refining Technologies Market Regional Analysis

- Asia-Pacific: The Asia-Pacific is expected to dominate the antimony refining technologies market largely because China has a large antimony reserve and established antimony refining facilities. Furthermore, the Asia-Pacific region has strong industrial demand across its various sectors, especially in electronics, automotive, construction, and chemical sectors, with high-purity antimony, which is excessively used. Antimony refiners in the region are deploying advanced pyrometallurgical, hydrometallurgical antimony refining technologies and electrolytic technologies for enhanced recovery, improved product quality, and improved energy efficiency. Also, the regional antimony refining market is primarily aided by government measures, which stimulate mineral exploration and the growth of its industries. With rising levels of environmental regulation, companies are also integrating sustainable antimony refinery practices, securing a more dominant position for the Asia-Pacific region as the key to antimony refining and supply on a global basis.

________________________________________

Antimony Refining Technologies Market Scope:

| Report Metric | Details |

|---|---|

| Total Market Size in 2026 | USD 115.684 million |

| Total Market Size in 2031 | USD 141.312 million |

| Growth Rate | 4.08% |

| Study Period | 2021 to 2031 |

| Historical Data | 2021 to 2024 |

| Base Year | 2025 |

| Forecast Period | 2026 – 2031 |

| Segmentation | Refining Method, Application, End-User, Geography |

| Geographical Segmentation | North America, South America, Europe, Middle East and Africa, Asia Pacific |

| Companies |

|

Antimony Refining Technologies Market Segmentation:

- By Refining Method

- Pyrometallurgical Refining

- Hydrometallurgical Refining

- Electrolytic Refining

- By Application

- Flame Retardants

- Lead-Acid Batteries

- Alloys

- Chemicals

- Other

- By End User

- Electronics & Electricals

- Automotive

- Construction

- Chemicals & Pharmaceuticals

- Defense & Ammunition

- Other

- By Geography

- North America

- United States

- Canada

- Mexico

- South America

- Brazil

- Argentina

- Others

- Europe

- United Kingdom

- Germany

- France

- Italy

- Others

- Middle East and Africa

- Saudi Arabia

- UAE

- Others

- Asia Pacific

- Japan

- China

- India

- South Korea

- Taiwan

- Others

- North America