Report Overview

Green Manufacturing Robotics Market Highlights

Green Manufacturing Robotics Market Size:

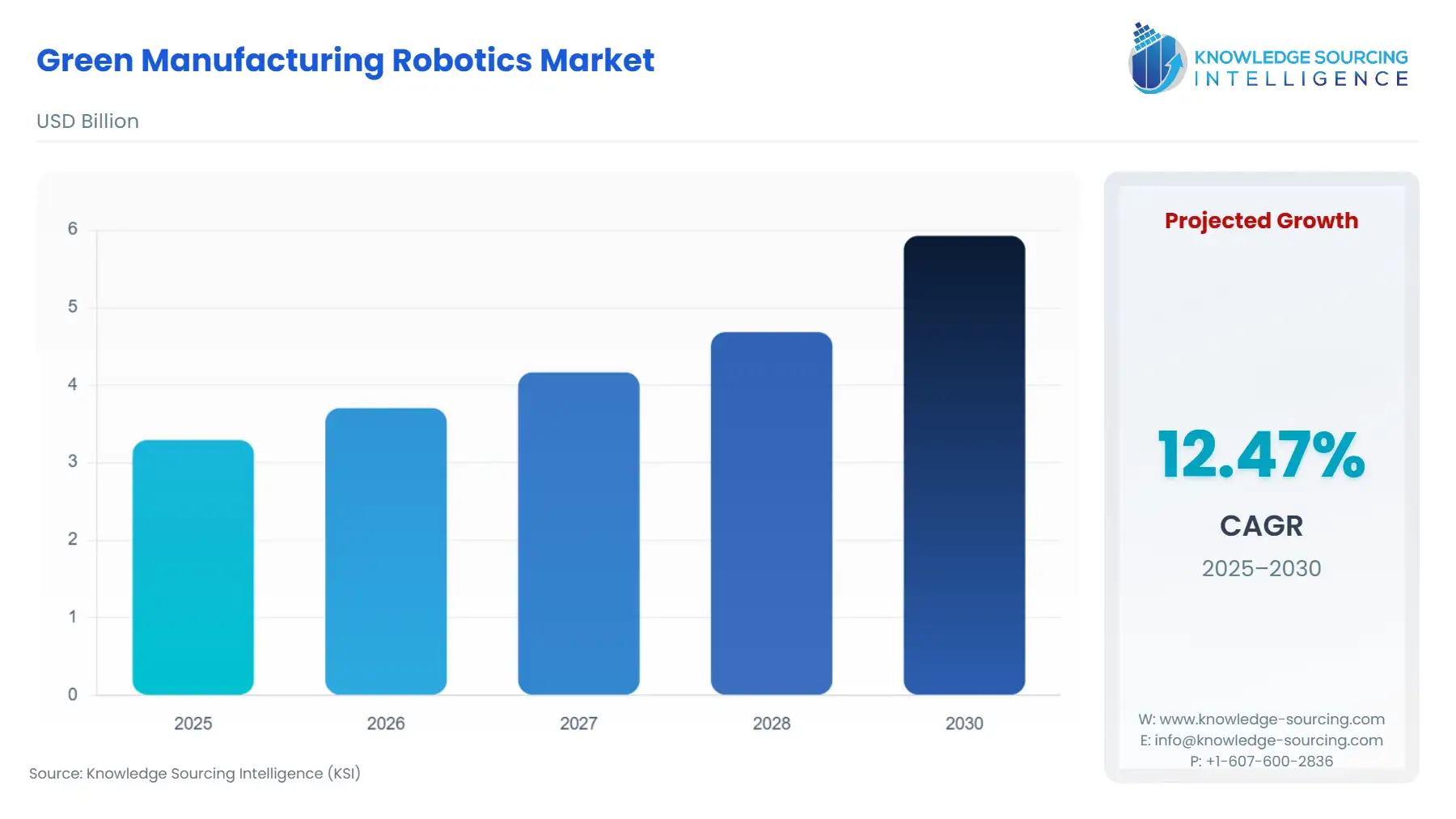

The Green Manufacturing Robotics Market is expected to grow at a CAGR of 12.47%, rising from USD 3.293 billion in 2025 to USD 5.927 billion by 2030.

The Green Manufacturing Robotics Market is strong as industries try to reduce carbon reduction and increase the efficiency of operations. Robotics plays a central role in sustainable manufacturing as it limits waste, economizes energy consumption, and enables precision-directed processes. Many companies are incorporating AI, IoT and machine learning into robotic systems to enhance performance and monitor real-time energy needs. Policies and incentives are being initiated by governments in the key economies to enhance environmentally friendly automation and green commercial practices.

The adoption of collaborative and autonomous robots is helping industries achieve their sustainability goals while maintaining productivity levels. Leading the implementation of green robotics to obviate environmental shortfalls and economize in operational costs are industries such as automotive, electronics and processing of foods. All in all, the market is poised for remarkable growth as sustainability evolves into a strategic commercial objective and technological innovations serve to make robotics cleaner, smarter and more efficient.

Green Manufacturing Robotics Market Overview & Scope:

The Green Manufacturing Robotics Market is segmented by:

- By Type: The market is divided into industrial robots, collaborative robots, and data mobile robots. Industrial robots support large-scale manufacturing where great precision is required. Collaborative robots (cobots) support human productivity, which enhances production flexibility. Mobile robots permit improved movement of materials and waste management in green production plants.

- By Application: Applications include assembly, material handling, painting and coating, packaging, and inspection. The leading applications are assembly and materials handling by virtue of their impressive capabilities to help facilitate and streamline various operations, while reducing energy consumption and waste generation, which is the essence of green production.

- By End-Use Industry: The principal end-use industries are automotive, electronics, pharmaceuticals, food & beverages, and heavy machinery. The automotive and electronics industries will be the leaders in adoption, driven by the need for compliance with stringent sustainability laws and the need for improved, cleaner, energy-efficient production lines.

- Region: Geographically, the market is expanding at varying rates depending on the location.

________________________________________

Top Trends Shaping the Green Manufacturing Robotics Market:

Integration of AI and IoT in Green Robotics

Manufacturers are increasingly turning to the integration of AI and IoT in robots to monitor energy use and maximize the efficiency of manufacturing production. These intelligent robots are able to change the use of operations in real time to lessen material waste and minimize the company’s carbon footprint. Because of this, environmental sustainability and industrial automation can co-exist.

Rise of Energy-Efficient Collaborative Robots (Cobots)

Collaborative robots that use low-energy systems are becoming increasingly common in green factories. Due to their size, their energy efficient soft motors and their ability to complete small and sustainable operations, they are becoming increasingly desirable in areas of industry that have net-zero production parameters.

________________________________________

Green Manufacturing Robotics Market Growth Drivers vs. Challenges:

Drivers:

- Global Push for Sustainable Manufacturing: Governments around the world are introducing policies to create low-emission and resource efficient production systems. Through strategies such as the European Union’s Green Deal and Japan’s Green Growth Strategy, governments are encouraging manufacturers to integrate the use of robotics to reduce waste, maximize efficiency of operations, and to meet commitments of carbon neutrality.

- Cost Reduction and Operational Efficiency: Green manufacturing robotics allow a major reduction in costs involved in manufacturing due to diminished consumption of energy, reduced errors and maximization of flow of operations. Industries are using them not only as a means of complying with sustainability mandates, but also as a means of increasing profits in the longer term through more intelligent applications of automation.

Challenges:

- High Initial Investment Costs: The integration of eco-friendly robotics involves substantial upfront costs, including system installation, maintenance, and staff training. Small and medium enterprises often find it difficult to justify these expenses without short-term returns.

________________________________________

Green Manufacturing Robotics Market Regional Analysis:

- Europe: The green manufacturing robotics market is growing rapidly due to strict environmental policies, modern industrial robotics as well as active environmental programs. The EU’s Green Deal, which calls for carbon neutrality by 2050, has helped the adoption of energy efficient robots in industries such as automotive, electronics and consumer goods. The leading markets in this segment are Germany, France and the Netherlands, with their established robotic environment and focus of integrating renewable energy in production. Investments in the circular economy and government incentives towards low-emission technologies, are also boosting growth. Also, co-operation with robotics and research centres is helping to achieve continuous innovative steps in the green automation systems.

________________________________________

Green Manufacturing Robotics Market Scope:

| Report Metric | Details |

|---|---|

| Total Market Size in 2026 | USD 3.293 billion |

| Total Market Size in 2031 | USD 5.927 billion |

| Growth Rate | 12.47% |

| Study Period | 2021 to 2031 |

| Historical Data | 2021 to 2024 |

| Base Year | 2025 |

| Forecast Period | 2026 – 2031 |

| Segmentation | Robot Type, Component, Application, Geography |

| Geographical Segmentation | North America, South America, Europe, Middle East and Africa, Asia Pacific |

| Companies |

|

Green Manufacturing Robotics Market Segmentation:

- By Robot Type

- Industrial

- Collaborative

- Service

- Others

- By Component

- Hardware

- Software

- Services

- By Application

- Automotive

- Electronics

- Aerospace

- Solar & Wind

- Logistics

- Others

- By Geography

- North America

- United States

- Canada

- Mexico

- South America

- Brazil

- Argentina

- Others

- Europe

- United Kingdom

- Germany

- France

- Italy

- Others

- Middle East and Africa

- Saudi Arabia

- UAE

- Others

- Asia Pacific

- Japan

- China

- India

- South Korea

- Taiwan

- Others

- North America