Report Overview

Pressure Gauges Market - Highlights

Pressure Gauges Market Size:

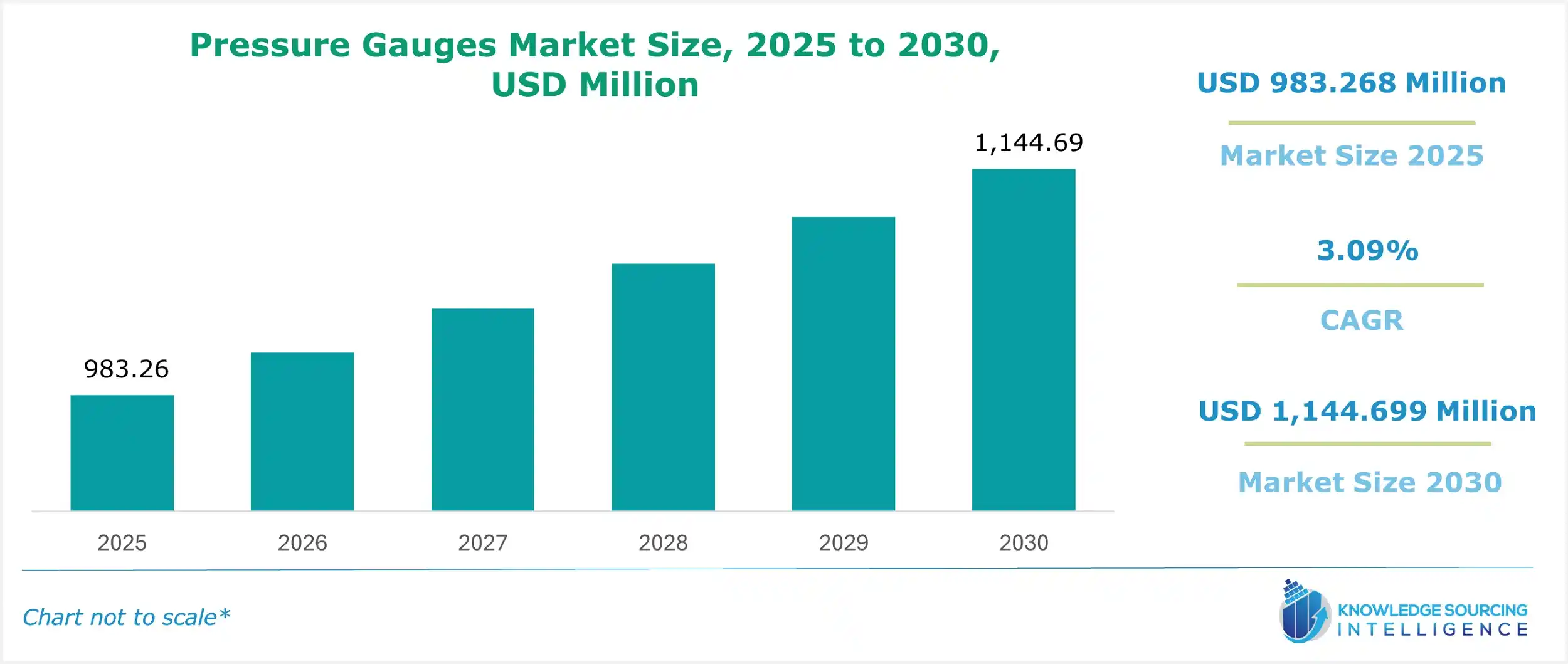

Pressure Gauges Market is anticipated to increase at a 3.0% CAGR, from USD 983.268 million in 2025 to USD 1173.889 million in 2031.

Pressure Gauges Market Overview:

Pressure gauges, alternatively referred to as pressure meters or vacuum gauges, serve as essential instruments utilized to determine the internal pressure of substances within a particular system. These devices are widely employed in various industrial facilities due to their frequent usage and importance in monitoring and maintaining operational conditions. They are broadly classified into three types: absolute pressure gauge, differential pressure gauge, and diaphragm pressure gauge. The bolstering growth of various sectors, namely pharmaceuticals, chemicals, and oil & gas, is a prominent driver propelling the pressure gauge market growth.

The pressure gauge market is evolving rapidly, driven by advanced technologies like WirelessHART, Bluetooth pressure gauges, and LoRaWAN pressure sensors. These innovations enable real-time pressure monitoring, enhancing operational efficiency in industries such as oil and gas, manufacturing, and HVAC. Predictive maintenance pressure solutions leverage data logging pressure gauges to anticipate equipment failures, reducing downtime. Remote pressure sensing capabilities allow seamless integration into IoT ecosystems, providing precise, real-time data for process optimization. These advancements cater to industry experts seeking robust, scalable solutions for critical pressure monitoring applications, ensuring safety, compliance, and enhanced system performance in demanding industrial environments.

Pressure Gauges Market Trends:

The pressure gauge market is undergoing a digital transformation in pressure measurement, propelled by Industry 4.0 pressure gauges and smart factory sensors. These advanced devices integrate with IoT platforms, enabling seamless data analytics and automation. Sensor miniaturization trends are driving the development of compact, high-precision gauges suitable for space-constrained applications in automotive and medical sectors. These innovations enhance real-time monitoring and predictive maintenance, optimizing operational efficiency. As such, these smart, connected solutions are adopted to meet the demands of modern manufacturing, ensuring greater accuracy, reliability, and integration in increasingly automated and data-driven industrial environments.

Pressure Gauges Market Segmentation Analysis:

The rising pharmaceuticals sector drives the pressure gauge market growth.

Pressure gauges are utilized in pharmaceutical equipment such as reactors, filtration systems, distillation columns, and sterilization chambers to ensure precise pressure management and prevent any deviations that could compromise the safety of the operations. The pharmaceutical sector is playing a significant role in boosting the pressure gauge industry, and as the industry strives to maintain strict quality control and ensure the safety of its manufacturing processes, pressure gauges are essential instruments for monitoring and regulating critical pressure. According to the European Federation of Pharmaceutical Industries and Associations, the European pharmaceutical industry demonstrated remarkable progress in 2021. Production figures surged from approximately 286,697 units in 2020 to a substantial increase of 300,000 units in 2021. This upward trend in production indicates a positive development for the Eurozone's pharmaceutical sector.

Booming chemical industry bolsters the pressure gauge market growth.

Chemical plants and facilities require accurate and reliable pressure gauges to ensure the safe and efficient operation of various processes. Pressure gauges are utilized in critical applications such as monitoring and controlling pressure in reactors, pipelines, storage tanks, and other equipment. As a result, their growing applicability is expanding the pressure gauge market size. According to the European Chemical Industry Council, there is substantial growth in global chemical sales, with a remarkable increase of 15.2% from €3,494 billion in 2020 to €4,026 billion in 2021. Among the leading contributors to these sales, the EU27 chemical industry secures the second position with a share of 14.7%.

The growing oil & gas sector has enhanced the pressure gauge market size.

The pressure gauge market receives a substantial boost from the oil and gas sector as the pressure gauges are utilized across various critical applications such as drilling, exploration, production, refining, and transportation of oil and gas. Their primary function is to monitor and control pressure levels in essential components such as pipelines, storage tanks, wellheads, and other equipment. By ensuring accurate pressure measurements, pressure gauges contribute to the safety and efficiency of oil and gas operations. The growing oil demand on a global scale, coupled with the establishment of exploration projects, has propelled the demand for pressure gauges. For instance, according to the International Energy Agency, the global oil demand is estimated to increase by 6% from 2022 to 2028, reaching a significant volume of 105.7 million barrels per day.

Pressure Gauges Market Geographical Outlook:

Asia-Pacific region is anticipated to dominate the market.

The Asia-Pacific region, with its dynamic industrial landscape, has emerged as a dominant player in the global pressure gauge industry. According to the Department of Pharmaceuticals, by 2025, the medical device industry in India will have the potential to achieve a remarkable market value of $50 billion. As the 4th largest medical devices market in Asia, India follows Japan, China, and South Korea. Additionally, it holds a prominent position among the top 20 global medical device markets worldwide. Additionally, in the March 2022 press release, the Australian Government announced a substantial investment of $132 $133 billion in 2022–23 for significantly bolstering the health system, with a rise to $140 billion in 2025–26. This commitment amounts to a total of $537 billion over the next four years, reflecting a strong focus on building a robust healthcare infrastructure for the future.

Pressure Gauges Market Growth Drivers:

Alternative availability is restraining the pressure gauges industry growth.

The growing acceptance of electronic monitoring systems, such as remote monitoring and control solutions, has resulted in a decreased dependency on conventional pressure gauges. One of the primary advantages of electronic monitoring systems is their ability to provide real-time data. Unlike pressure gauges that offer point-in-time measurements, electronic monitoring systems continuously gather and transmit data, allowing for immediate analysis and decision-making. This real-time monitoring capability enables industries to promptly identify and address any deviations or abnormalities in pressure levels. Consequently, this trend has the potential to restrict the expansion of the pressure gauge market as electronic monitoring systems gain preference.

Pressure Gauges Market Company Products:

A leading manufacturer introduced a WirelessHART-enabled pressure gauge, offering secure, long-range data transmission for real-time monitoring in hazardous industrial environments, enhancing safety and efficiency

Model JH: Honeywell International presents the impressive Model JH, a state-of-the-art Digital Pressure Gauge renowned for its high-pressure capabilities. Designed for demanding applications, it offers an exceptional pressure range spanning from 15,000 psi to an impressive 60,000 psi. With a remarkable accuracy of 0.2% FS (Full Scale), this gauge ensures precise and reliable measurements.

Rose Mount Wireless Pressure Gauge: Emerson Electric introduces the cutting-edge Rosemount Wireless Pressure Gauge, a product designed with a durable and resilient construction that overcomes common failures associated with traditional gauges. Powered by industry-proven sensor technology, this pressure gauge offers enhanced resistance and reliability. With a remarkable lifespan of up to 10 years of maintenance-free operation,

1550/1553 Liquid Filled Pressure Gauge: A Stainless-Steel Gauge specifically designed for reliable performance by AMETEK Inc., which is equipped with a crimped ring and a dual-scale psi/kPa dial as standard, this gauge offers versatility and ease of use. It excels in environments characterized by high vibration, pulsation, pressure spikes, and condensation buildup.

List of Top Pressure Gauges Companies:

Honeywell International Inc.

Emerson Electric Co

AMETEK.Inc.

WIKA Group

Omega Engineering, Inc

Pressure Gauges Market Scope:

| Report Metric | Details |

|---|---|

| Study Period | 2021 to 2031 |

| Historical Data | 2021 to 2024 |

| Base Year | 2025 |

| Forecast Period | 2026 – 2031 |

| Companies |

|

Report Metric | Details |

Pressure Gauges Market Size in 2025 | USD 983.268 million |

Pressure Gauges Market Size in 2030 | USD 1,144.699 million |

Growth Rate | CAGR of 3.09% |

Study Period | 2020 to 2030 |

Historical Data | 2020 to 2023 |

Base Year | 2024 |

Forecast Period | 2025 – 2030 |

Forecast Unit (Value) | USD Billion |

Segmentation |

|

Geographical Segmentation | North America, South America, Europe, Middle East and Africa, Asia Pacific |

List of Major Companies in the Pressure Gauges Market |

|

Customization Scope | Free report customization with purchase |

Pressure Gauges Market Segmentation:

By Type

Absolute Pressure Gauge

Differential Pressure Gauge

Diaphragm Pressure Gauge

Others

By Material

Brass

Steel

Plastic

By Product Type

Digital

Analog

By End-User

Automotive

Chemical

Pharmaceuticals

Oil & Gas

Aerospace & Defence

Others

By Geography

North America

USA

Canada

Mexico

South America

Brazil

Argentina

Others

Europe

Germany

France

United Kingdom

Spain

Others

Middle East and Africa

Saudi Arabia

UAE

Others

Asia Pacific

China

India

Japan

South Korea

Indonesia

Thailand

Others