Biomedical textiles are adapted for many medical and surgical applications. The major use of biomedical textiles is medical apparel. The textiles in fiber and fabric form are used as implants, filters, and

surgical dressings. Recent advances in medical textile production have made it possible for implants to aid or replace damaged tissues or organs. These products are used to repair the body, whether it is

wound closure (sutures) or replacement surgeries (vascular grafts or artificial ligaments).

The growing use of bio-medical textiles is due to the challenges associated with the complete transplant, such as rejection, immunosuppressants, psychological difficulties, physiological difficulties, donor organ shortage, etc. Hence, medical communities are using artificial substitutes such as biotextiles. This substitute material used to replace the body part is called a prosthesis. The most common use of the prosthesis is in the knees or hips. The main focus of using bio-medical textiles is to serve the purpose they are applied for, such as sutures requiring a biodegradable textile.

Another example of such an example is artificial ligaments. The artificial ligaments, LIGASTIC, offered by Orthomed, are used to replace or reinforce an existing ligament. These are utilized for at least 6 months in ACL (anterior cruciate ligament) reinforcement cases or permanently for replacement cases. It is made from Polyethylene Terephthalate (PET). These are knitted in nondeforming and non-wrappable chains. The fibers are orientated longitudinally in the axis of the ligament and are straight and parallel at maximum extension. The porosity of 400?m facilitates colonization, which allows the reinforcement or the replacement. The product is available in several sizes and shapes, following the procedures.

There are several major applications of bio-medical textiles in the field, such as wound treatment and

cardiovascular, where it is utilized for the aortic and mitral transcatheter valve skirts, atrial appendage occlusion device coverts, or endovascular stent-grafts. In orthopedic applications, the sutures and assemblies, joint and ligament fixation, and spinal fixation tethers. For tissue engineering with cell scaffolds and resorbable wound healing materials.

Cardiovascular Applications

Cardiovascular diseases (CVDs) and ailments are increasing at a very alarming pace globally. According to the WHO (World Health Organization), cardiovascular diseases are the leading cause of death globally. CVDs include disorders of the heart and blood vessels and include coronary heart disease, cerebrovascular disease, rheumatic heart disease, and others. Both behavioral and environmental factors use these. The major behavioral factors for the increased risk of CVDs are unhealthy diet, physical inactivity, tobacco use, and use of alcohol. Environmental risk factors include air pollution as an important factor. These factors lead to complications such as raised

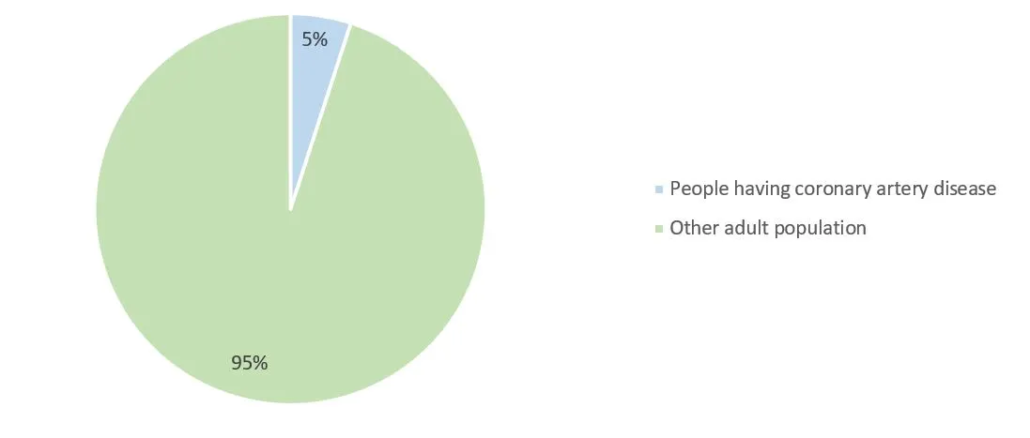

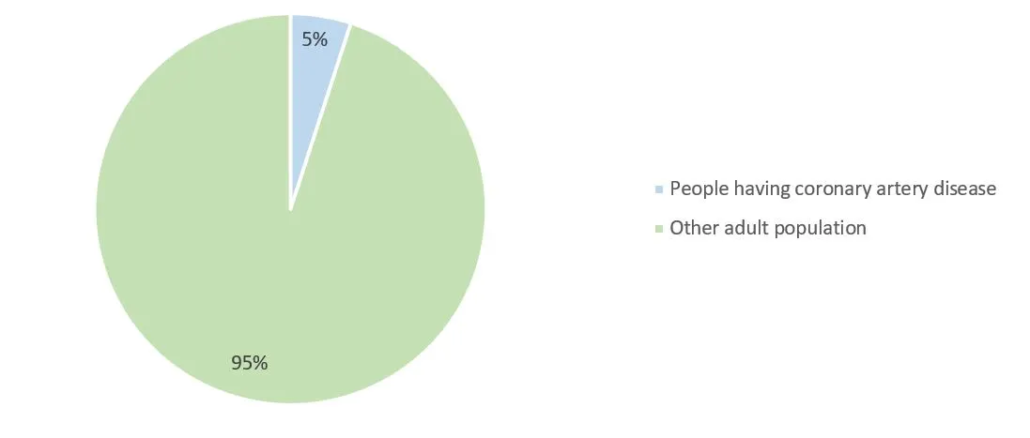

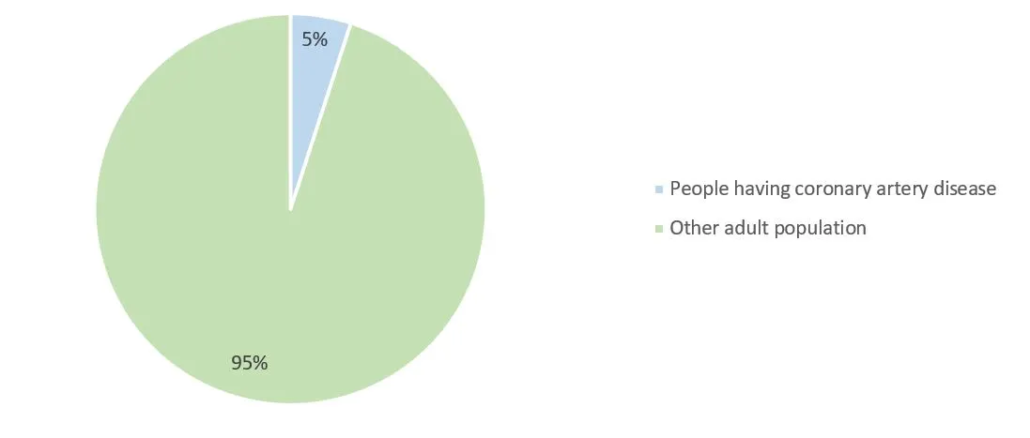

blood pressure, raised blood glucose, raised blood lipids, and overweight and obesity, which would lead to heart attack, stroke, heart failure, and others. In 2022, coronary heart disease (CAD) killed 371,506 people in the United States. About 1 in 20 adults aged 20 and older have CAD, i.e., 5% of the total population.

Figure 1: People With Coronary Artery Disease (Cad), (20 Y and Above), United States, in %, 2022

Source: CDC (Centre for Disease Control)

Source: CDC (Centre for Disease Control)

With increased numbers of patients and considerable diagnostic and technological advancements, vascular diseases are becoming important in general and clinical practices. The design and manufacturing of synthetic vascular prostheses have been challenging in research and development. The materials used need to meet all the requirements. The important aspects are porosity, compliance, and biodegradability.

The general application for the lower-profile devices and less invasive cardiovascular and endovascular procedures/applications included heart valve replacement, aortic arch reinforcement, stent graft covering, carotid artery repair fabric, tissue grafts, and others. The key benefits included the less invasive, lower profile, controlled density and porosity, flexibility, shape transformation, high tensile strength, and biocompatibility, among others.

DSM offers a biomaterial portfolio for cardiovascular applications, as shown in the following table.

Table 1.1: DSM Biomaterial Portfolio for Cardiovascular

| Companies |

Product |

| Structural Heart |

Polyurethanes are a biocompatible material that improves the durability and overall effectiveness of structural heart solutions. These are included with catheter-based therapies like heart valve repair and replacement. Heart valve replacement (aortic, mitral, and tricuspid), LAAO (Left Atrial Appendage Occlusion), and mitral/tricuspid valve repair (through clips or annuloplasty) are also part of the solutions. |

| Vascular Closure |

For the puncture sites, fast healing, vascular interventions, and fully resorbable collagen materials are ideal choices. Collagen are naturally derived biomaterials. It is used for access vessel sealing post-catheterization. This is to provide rapid hemostasis, thus lowering intraprocedural bleeding. DSM Biomedical is a trailblazer in this field. The company can give the collagen with a source available in multiple shapes and sizes, including a plug or patch. |

| Interventional Cardiology |

They manufacture advanced biomaterials for catheter-based therapies. Both catheters and their various accessory devices use hydrophilic lubricious coatings. Balloon valvuloplasty, coronary and peripheral angioplasty and stenting, and cardiac catheterization are appropriate choices for these materials. |

| Cardiac Assist Devices |

DSM offers a range of hemocompatible and durable biomaterials to create less invasive cardiac assist devices that optimize cardiac function. These medical-grade materials are ideal for multiple-component applications, such as LVADs and other ventricular assist devices. Further innovation would create medical polyurethanes, enabling precision molding and coating. |

Neurovascular Applications

According to the AANS (American Association of Neurological Surgeons), an estimated 30,000 people in the United States experience a ruptured cerebral aneurysm. Among them, as many as 6 percent may have an unruptured aneurysm. The cerebrovascular disease includes disorders in which the brain is temporarily or permanently affected by ischemia or bleeding.

Several companies are developing advanced materials for

biomedical textiles to enable minimally invasive expansion and compaction of critical neurovascular devices for aneurysm repair and stroke prevention and treatment.

Secant Group offers textiles for neurovascular devices used for diverting blood flow, retrieving blood clots, or preventing or reducing plaque debris. The company specializes in developing products to shorten lead times, limit development costs, and deliver a prototype in a limited time. Customization and fabric modification facilities are available in the product development process to meet the requirements.

Secant Group offers neurovascular textile solutions for creating a new device or enhancing a predicate device. Manufacturers can obtain a broad portfolio of advanced textile solutions and services tailored to neurovascular devices.

Table 1.2: Secant Group, Neurovascular Textile Solutions

| Companies |

Product |

| Neurovascular Aneurysm Repair |

Flow diverter components and Intra saccular flow disruption components |

| Ischemic Stroke Prevention & Treatment |

Clot retrieval thrombectomy components and Embolic protection filter components |

| Materials |

Cobalt-chromium, Nitinol, Platinum, and Specialty alloys |

| Medical Textile-forming Technologies |

Braiding, Knitting, and Weaving |

Orthopedic Applications-

There are multiple orthopedic applications, such as minimally invasive solutions for bone grafting and fusion, spinal motion preservation, tissue fixation, cartilage, tendon, ligament, and meniscal repair. The major aspect of the development of orthopedic devices is identifying the most appropriate textile material to utilize. The textile material for orthopedic devices can be applied as flexible structures for tissue reinforcement and joint support and to join materials and secure implants in the body. The structures that are made from bio textiles are bone anchors, bone containment bags, high-strength sutures, scaffolds for load-sharing, and scaffolds for soft tissue repair, among others.

Table 1.3: Orthopedics, Biomedical Textiles, New Developments

| Companies |

Description |

| Riverpoint Medical and DSM Biomedical |

In March 2023, Riverpoint Medical announced they had the exclusive license of a proprietary Osteoconductive (OC) Coating Technology from DSM Biomedical. Osteoconduction is the technology of bone-forming cells to move across a scaffold and replace it with a new bone. Osteoconductive coatings are commonly used in orthopedic and dental implants but are not widely available in implantable textiles; by this, the company aspires to create an improved environment for enhanced bone attachment. The DSM Biomedical created the proprietary OC coating technology and further developed it into a full-scale production line by Riverpoint. |

| Thuasne and Corflex |

In May 2024, Thuasne acquired US company Corflex, Inc. to expand its global product portfolio and strengthen its US market presence, which specializes in orthopedic bracing. This is significant in Thuasne's growth strategy, for its expansion in US and international markets. Both companies would leverage their brand recognition and market presence for further growth. |

General Applications

Non-toxicity, nonallergenic, and able to be sterilized are the major characteristics of medical textiles, which makes them appropriate for wound care applications. The major applications of these materials are to provide protection against infection, absorb blood, promote healing, and apply medication to the wound. The wound dressings are composite materials consisting of an absorbent layer between a wound contact layer and a flexible base material. The use of healing property fibers like collagen, alginate, and chitin is relevant in the treatment.

Soft-tissue implants are a major application of these materials. They are used because of their strength and flexibility. For both reconstructive and corrective surgery, soft-tissue implants are employed for the replacement of tendons, ligaments, and cartilage.

Conclusion

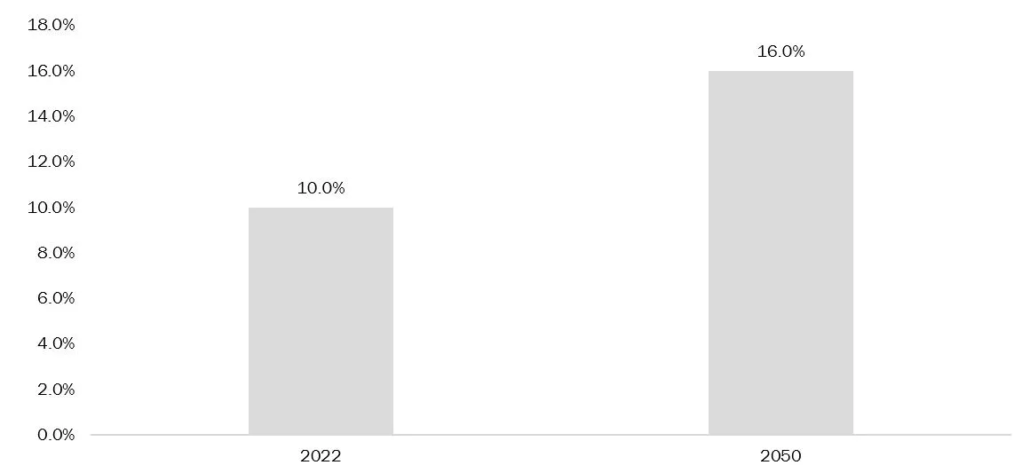

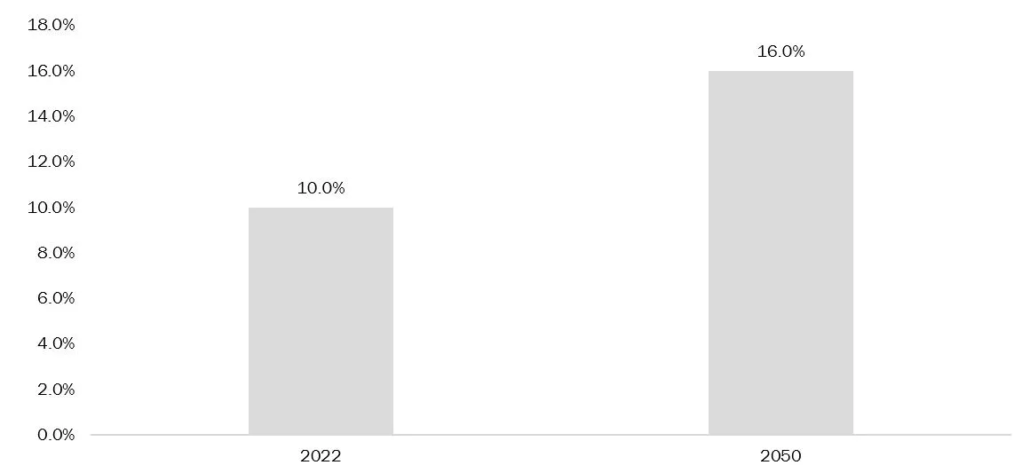

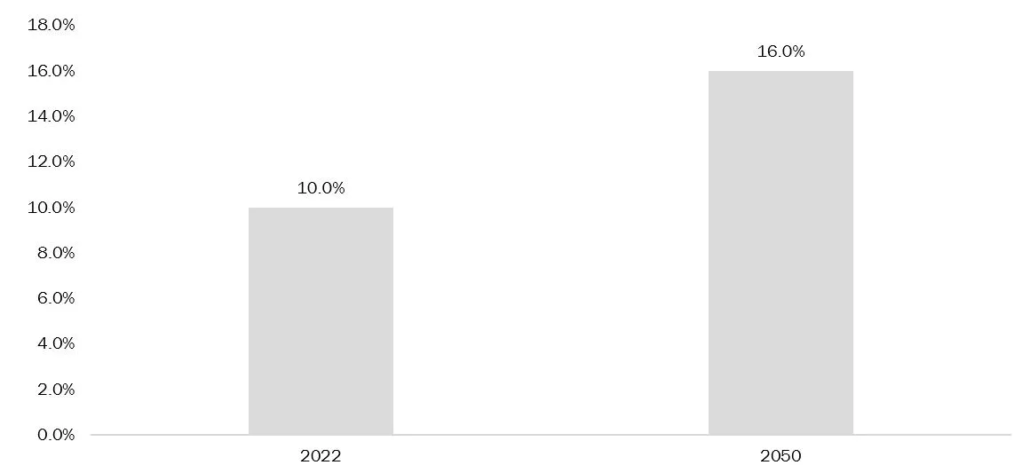

The growing elderly population worldwide is leading to increasing age-related physiological issues. This growing elderly population has orthopedic, spinal, cardiovascular, and other major disorders. According to the World Population Prospects 2022, the population above the age of 65 is growing more rapidly. The percentage of the global population aged 65 and above is expected to rise from 10% in 2022 to 16% in 2050, this is a significant surge in the geriatric population.

Figure 2: Proportion of People Aged 65 Years and Above, in %, 2022 and 2050

Source: United Nations

Source: United Nations

This increase in geriatric population is occurring at a significant pace in developing countries as well as developed countries. This is historically significant as the population requires adaptations to how societies are structured across all sectors. This includes healthcare needs, social care, innovation-related healthcare, etc.

Several major companies are taking steps in the expansion of the biomedical textiles industry. Cortland Biomedical is a major player that customizes designs and manufactures biomedical textile structures. They have years of experience in medical textile engineering methods, including knitting, braiding, and weaving. In January 2024, announced the expansion of its weaving capabilities by incorporating two additional Jacquard Looms. This strategic move would enhance the company’s capacities and advancements in medical textiles. Cortland Biomedical specializes in plain and narrow weave fabrics, including shuttle and rapier weaving. It excels in creating unique three-dimensional structures for applications like vascular grafts. These woven textiles are specifically designed for vascular and abdominal aortic aneurysm grafts and ensure limited blood flow.

In April 2022, Integer Holdings Corporation acquired Connemara Biomedical Holdings Teoranta. The acquisition also included operating subsidiaries Aran Biomedical and Proxy Biomedical. It was acquired for €120 million, with up to an additional €10 million of contingent consideration payable based on Aran’s achievement of 2022 revenue growth. Aran Biomedical specializes in the design, development, and manufacturing of solutions for

medical devices, it generated sales of $17 million in 2021. These developments in the industry would lead to the overall growth of the application of biomedical textiles in wound care and surgical domain.

Source: CDC (Centre for Disease Control)

With increased numbers of patients and considerable diagnostic and technological advancements, vascular diseases are becoming important in general and clinical practices. The design and manufacturing of synthetic vascular prostheses have been challenging in research and development. The materials used need to meet all the requirements. The important aspects are porosity, compliance, and biodegradability.

The general application for the lower-profile devices and less invasive cardiovascular and endovascular procedures/applications included heart valve replacement, aortic arch reinforcement, stent graft covering, carotid artery repair fabric, tissue grafts, and others. The key benefits included the less invasive, lower profile, controlled density and porosity, flexibility, shape transformation, high tensile strength, and biocompatibility, among others.

DSM offers a biomaterial portfolio for cardiovascular applications, as shown in the following table.

Table 1.1: DSM Biomaterial Portfolio for Cardiovascular

Source: CDC (Centre for Disease Control)

With increased numbers of patients and considerable diagnostic and technological advancements, vascular diseases are becoming important in general and clinical practices. The design and manufacturing of synthetic vascular prostheses have been challenging in research and development. The materials used need to meet all the requirements. The important aspects are porosity, compliance, and biodegradability.

The general application for the lower-profile devices and less invasive cardiovascular and endovascular procedures/applications included heart valve replacement, aortic arch reinforcement, stent graft covering, carotid artery repair fabric, tissue grafts, and others. The key benefits included the less invasive, lower profile, controlled density and porosity, flexibility, shape transformation, high tensile strength, and biocompatibility, among others.

DSM offers a biomaterial portfolio for cardiovascular applications, as shown in the following table.

Table 1.1: DSM Biomaterial Portfolio for Cardiovascular

Source: United Nations

This increase in geriatric population is occurring at a significant pace in developing countries as well as developed countries. This is historically significant as the population requires adaptations to how societies are structured across all sectors. This includes healthcare needs, social care, innovation-related healthcare, etc.

Several major companies are taking steps in the expansion of the biomedical textiles industry. Cortland Biomedical is a major player that customizes designs and manufactures biomedical textile structures. They have years of experience in medical textile engineering methods, including knitting, braiding, and weaving. In January 2024, announced the expansion of its weaving capabilities by incorporating two additional Jacquard Looms. This strategic move would enhance the company’s capacities and advancements in medical textiles. Cortland Biomedical specializes in plain and narrow weave fabrics, including shuttle and rapier weaving. It excels in creating unique three-dimensional structures for applications like vascular grafts. These woven textiles are specifically designed for vascular and abdominal aortic aneurysm grafts and ensure limited blood flow.

In April 2022, Integer Holdings Corporation acquired Connemara Biomedical Holdings Teoranta. The acquisition also included operating subsidiaries Aran Biomedical and Proxy Biomedical. It was acquired for €120 million, with up to an additional €10 million of contingent consideration payable based on Aran’s achievement of 2022 revenue growth. Aran Biomedical specializes in the design, development, and manufacturing of solutions for medical devices, it generated sales of $17 million in 2021. These developments in the industry would lead to the overall growth of the application of biomedical textiles in wound care and surgical domain.

Source: United Nations

This increase in geriatric population is occurring at a significant pace in developing countries as well as developed countries. This is historically significant as the population requires adaptations to how societies are structured across all sectors. This includes healthcare needs, social care, innovation-related healthcare, etc.

Several major companies are taking steps in the expansion of the biomedical textiles industry. Cortland Biomedical is a major player that customizes designs and manufactures biomedical textile structures. They have years of experience in medical textile engineering methods, including knitting, braiding, and weaving. In January 2024, announced the expansion of its weaving capabilities by incorporating two additional Jacquard Looms. This strategic move would enhance the company’s capacities and advancements in medical textiles. Cortland Biomedical specializes in plain and narrow weave fabrics, including shuttle and rapier weaving. It excels in creating unique three-dimensional structures for applications like vascular grafts. These woven textiles are specifically designed for vascular and abdominal aortic aneurysm grafts and ensure limited blood flow.

In April 2022, Integer Holdings Corporation acquired Connemara Biomedical Holdings Teoranta. The acquisition also included operating subsidiaries Aran Biomedical and Proxy Biomedical. It was acquired for €120 million, with up to an additional €10 million of contingent consideration payable based on Aran’s achievement of 2022 revenue growth. Aran Biomedical specializes in the design, development, and manufacturing of solutions for medical devices, it generated sales of $17 million in 2021. These developments in the industry would lead to the overall growth of the application of biomedical textiles in wound care and surgical domain. Source: CDC (Centre for Disease Control)

With increased numbers of patients and considerable diagnostic and technological advancements, vascular diseases are becoming important in general and clinical practices. The design and manufacturing of synthetic vascular prostheses have been challenging in research and development. The materials used need to meet all the requirements. The important aspects are porosity, compliance, and biodegradability.

The general application for the lower-profile devices and less invasive cardiovascular and endovascular procedures/applications included heart valve replacement, aortic arch reinforcement, stent graft covering, carotid artery repair fabric, tissue grafts, and others. The key benefits included the less invasive, lower profile, controlled density and porosity, flexibility, shape transformation, high tensile strength, and biocompatibility, among others.

DSM offers a biomaterial portfolio for cardiovascular applications, as shown in the following table.

Table 1.1: DSM Biomaterial Portfolio for Cardiovascular

Source: CDC (Centre for Disease Control)

With increased numbers of patients and considerable diagnostic and technological advancements, vascular diseases are becoming important in general and clinical practices. The design and manufacturing of synthetic vascular prostheses have been challenging in research and development. The materials used need to meet all the requirements. The important aspects are porosity, compliance, and biodegradability.

The general application for the lower-profile devices and less invasive cardiovascular and endovascular procedures/applications included heart valve replacement, aortic arch reinforcement, stent graft covering, carotid artery repair fabric, tissue grafts, and others. The key benefits included the less invasive, lower profile, controlled density and porosity, flexibility, shape transformation, high tensile strength, and biocompatibility, among others.

DSM offers a biomaterial portfolio for cardiovascular applications, as shown in the following table.

Table 1.1: DSM Biomaterial Portfolio for Cardiovascular

Source: United Nations

This increase in geriatric population is occurring at a significant pace in developing countries as well as developed countries. This is historically significant as the population requires adaptations to how societies are structured across all sectors. This includes healthcare needs, social care, innovation-related healthcare, etc.

Several major companies are taking steps in the expansion of the biomedical textiles industry. Cortland Biomedical is a major player that customizes designs and manufactures biomedical textile structures. They have years of experience in medical textile engineering methods, including knitting, braiding, and weaving. In January 2024, announced the expansion of its weaving capabilities by incorporating two additional Jacquard Looms. This strategic move would enhance the company’s capacities and advancements in medical textiles. Cortland Biomedical specializes in plain and narrow weave fabrics, including shuttle and rapier weaving. It excels in creating unique three-dimensional structures for applications like vascular grafts. These woven textiles are specifically designed for vascular and abdominal aortic aneurysm grafts and ensure limited blood flow.

In April 2022, Integer Holdings Corporation acquired Connemara Biomedical Holdings Teoranta. The acquisition also included operating subsidiaries Aran Biomedical and Proxy Biomedical. It was acquired for €120 million, with up to an additional €10 million of contingent consideration payable based on Aran’s achievement of 2022 revenue growth. Aran Biomedical specializes in the design, development, and manufacturing of solutions for medical devices, it generated sales of $17 million in 2021. These developments in the industry would lead to the overall growth of the application of biomedical textiles in wound care and surgical domain.

Source: United Nations

This increase in geriatric population is occurring at a significant pace in developing countries as well as developed countries. This is historically significant as the population requires adaptations to how societies are structured across all sectors. This includes healthcare needs, social care, innovation-related healthcare, etc.

Several major companies are taking steps in the expansion of the biomedical textiles industry. Cortland Biomedical is a major player that customizes designs and manufactures biomedical textile structures. They have years of experience in medical textile engineering methods, including knitting, braiding, and weaving. In January 2024, announced the expansion of its weaving capabilities by incorporating two additional Jacquard Looms. This strategic move would enhance the company’s capacities and advancements in medical textiles. Cortland Biomedical specializes in plain and narrow weave fabrics, including shuttle and rapier weaving. It excels in creating unique three-dimensional structures for applications like vascular grafts. These woven textiles are specifically designed for vascular and abdominal aortic aneurysm grafts and ensure limited blood flow.

In April 2022, Integer Holdings Corporation acquired Connemara Biomedical Holdings Teoranta. The acquisition also included operating subsidiaries Aran Biomedical and Proxy Biomedical. It was acquired for €120 million, with up to an additional €10 million of contingent consideration payable based on Aran’s achievement of 2022 revenue growth. Aran Biomedical specializes in the design, development, and manufacturing of solutions for medical devices, it generated sales of $17 million in 2021. These developments in the industry would lead to the overall growth of the application of biomedical textiles in wound care and surgical domain.