The Basement of the Industry: The Role of Higher Olefins is fuelling the demand for Daily Essentials

Higher olefins are the organic compounds originating from petroleum or natural gas, they are the necessary source for the various industrial processes. Higher olefins serve as important chemicals intervening in the production of various chemical substances. These unique compounds are used as the base for a wide range of items such as detergents, cleaning agents, plastics, sunscreen, lubricants, and drilling fluids. Higher olefins play an important role in the process of production of polyethylene, polypropylene, and other important plastics. They serve as an intense feedstock in the process of manufacturing.

Furthermore, synthetic lubricants used in various vehicles and machinery will benefit from these higher olefins as they contribute to the formulation of high-performance synthetic lubricants. These higher olefins serve as the base materials for various industrial products, coatings, and detergents making a chemical compound a valuable chemical asset.

Global Production Trends

The production of higher olefins is growing with the Increasing need for products in the downstream industry and the expansion of shale gas production around the globe. The higher olefins market is driven by the increased global population and increase in standard of living cost, there is a surge in demand for plastics, lubricants, and chemicals derived from olefins. This surge in demand is anticipating the production of olefins, as these products play a vital role in various industries.

In the present scenario, the availability of shale gas in regions like the United States has transformed the production of higher olefins. Shale gas is used as one of the crucial raw material components for steam cracking, a procedure that converts natural gas reservoirs to higher olefins. The current presence of easily accessible shale gas is expected to sustainably influence the worldwide production of the higher olefins.

The increased prevalence of technological advancement of the higher olefins is positively impacting and growing the global production trend for them. For instance, an innovative development in naphtha cracking has been initiated the collaboration between Mitsui Chemicals, Microwave Chemicals, and Chiyoda Corporation has initiated the development of the advanced “M- cracker” technology. This technology utilizes microwave heat instead of normal heating procedures, aiming for a more nature-friendly approach to ethylene manufacturing, an important element in the petrochemical industry. These initiatives and the evolution in the field of technology enhance higher olefin production trends across the globe.

Higher olefins use cases

The higher olefins have several use cases that are enhancing their production and market around the globe. These use cases include detergents, lubricants, drilling fluids, waxes, lube oils, and agricultural chemicals for powering them, the growing use of plastics and detergents in the day-to-day life of consumers is increasing the need for higher olefins proportionally they are found in plastic items and detergents that the individuals use on daily basis.

The higher olefins are used in the lubricants industry where they are used in formulating high-performance lubricants. These high-performance synthetic oils provide enhanced performance in extreme heat temperatures and increased frequency between the oil change intervals are derived from the higher olefins.

Furthermore, the chemical sector uses higher olefins as the main raw material content for various products, such as surfactants found in detergents, cleansing agents, and personal care products or items. Alcohols originating from the higher olefins are necessary for the production of plasticizers, antifreeze, and a variety of industrial solvents. Additionally, higher olefins are key materials in the production of coatings, adhesives, and other specialized chemicals used in various applications.

Market Dynamics and Drivers

Several factors drive the higher olefins market, including a growing need for downstream industry products like refining crude oil, processing, and purifying natural gas coupled with the availability of shale gas in the regions of the United States has transformed the production of higher olefins with the growing amount of various chemicals globally has contributed significantly to the boosting the higher olefins market.

These higher olefins are the crucial components used to intervene in the creation of other chemicals and polymers. These chemicals are used in various products like detergents, agricultural chemicals, and drilling lubricants. Also, they play an important role in product solutions used as feedstock for alcohols, and neodecanoic acids are projected to contribute to the growing higher olefins market in the forecast period.

Furthermore, the growing frequency of industrialization, increased economic growth, expansion of construction, and infrastructure development, and the growing automotive industry are the factors that are predicted to drive the market growth as they have significant use for high olefins for various operations in a variety of industries.

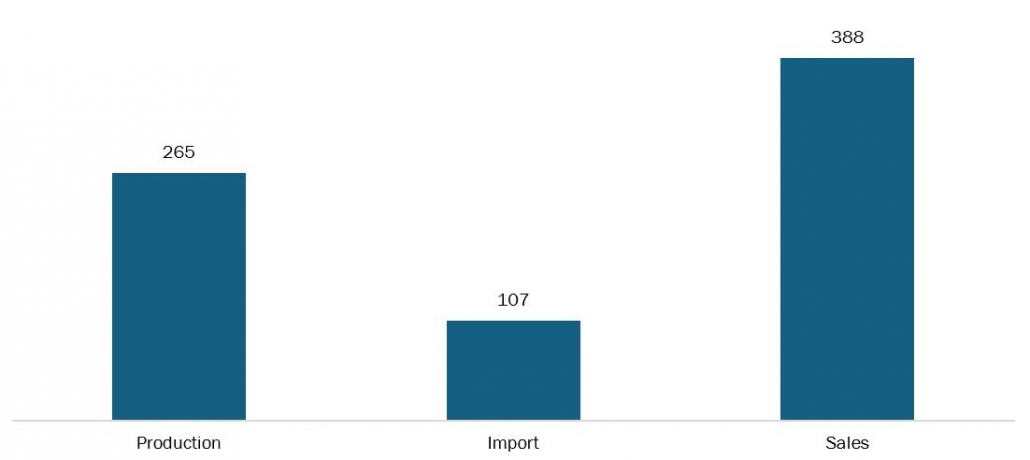

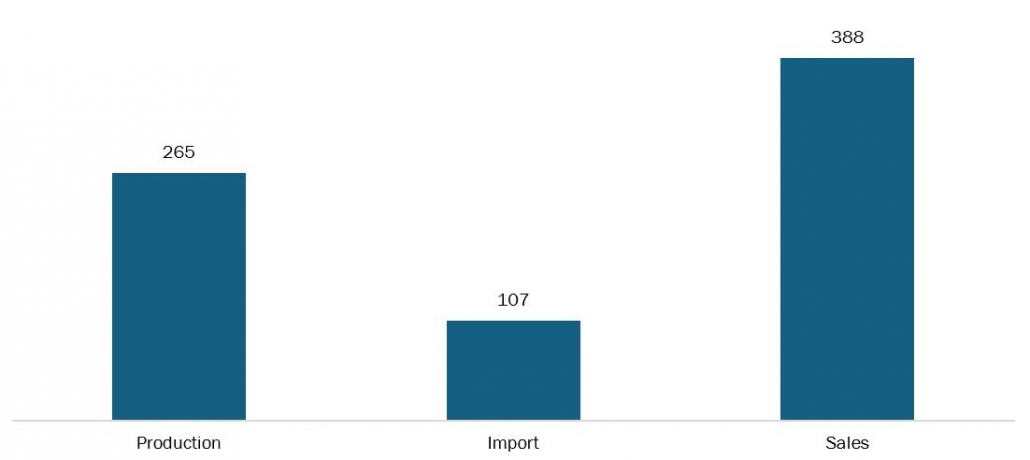

Higher olefins are the crucial primary components in the production of various chemicals like surfactants, lubricants, and agricultural chemicals with the increased production and sales of fertilizers in India, the demand for high olefins will rise proportionally. For instance, according to the Fertilizer Association of India, it states that in the year 2023, the overall production of various fertilizers was 265 lac tons with a sales volume of 388 lac tons.

Figure 1: Fertilizers Production, Import, and Sales in India (Qty. In Lac Tons)

Source: The Fertilizer Association of India.

Challenges and Constraints

Despite gaining popularity and use in various industries the higher olefin production face obstacles. Fluctuations in the prices of crude oil are the primary impact on the production expenses of higher olefins. Additionally, the traditional cracking procedure gives rise to impact on environmental issues. Stringent regulations and the emphasis on sustainability could result in a delay in the production process or necessitate the implementation of more nature-friendly technologies to reduce the environmental side effects.

Emerging opportunities and innovations

The potential for continued growth in the higher olefins industry is expanding. Indeed, from the point of gas shale, better-cracking technology like “M- Cracker”, which is driven both by cost-effectiveness and environmental sustainability might lead to bigger yields. The implementation of sustainable technologies, like microwave drying for naphtha cracking, is increasing and this is a great way for energy saving and waste disposal. For the promising scenario ahead, exploration through bio-based feedstocks with a renewable origin makes clear that greener means for higher olefins are better for various sectors that necessarily depend on these higher olefins.

Key Developments

Source: The Fertilizer Association of India.

Challenges and Constraints

Despite gaining popularity and use in various industries the higher olefin production face obstacles. Fluctuations in the prices of crude oil are the primary impact on the production expenses of higher olefins. Additionally, the traditional cracking procedure gives rise to impact on environmental issues. Stringent regulations and the emphasis on sustainability could result in a delay in the production process or necessitate the implementation of more nature-friendly technologies to reduce the environmental side effects.

Emerging opportunities and innovations

The potential for continued growth in the higher olefins industry is expanding. Indeed, from the point of gas shale, better-cracking technology like “M- Cracker”, which is driven both by cost-effectiveness and environmental sustainability might lead to bigger yields. The implementation of sustainable technologies, like microwave drying for naphtha cracking, is increasing and this is a great way for energy saving and waste disposal. For the promising scenario ahead, exploration through bio-based feedstocks with a renewable origin makes clear that greener means for higher olefins are better for various sectors that necessarily depend on these higher olefins.

Key Developments

Source: The Fertilizer Association of India.

Challenges and Constraints

Despite gaining popularity and use in various industries the higher olefin production face obstacles. Fluctuations in the prices of crude oil are the primary impact on the production expenses of higher olefins. Additionally, the traditional cracking procedure gives rise to impact on environmental issues. Stringent regulations and the emphasis on sustainability could result in a delay in the production process or necessitate the implementation of more nature-friendly technologies to reduce the environmental side effects.

Emerging opportunities and innovations

The potential for continued growth in the higher olefins industry is expanding. Indeed, from the point of gas shale, better-cracking technology like “M- Cracker”, which is driven both by cost-effectiveness and environmental sustainability might lead to bigger yields. The implementation of sustainable technologies, like microwave drying for naphtha cracking, is increasing and this is a great way for energy saving and waste disposal. For the promising scenario ahead, exploration through bio-based feedstocks with a renewable origin makes clear that greener means for higher olefins are better for various sectors that necessarily depend on these higher olefins.

Key Developments

Source: The Fertilizer Association of India.

Challenges and Constraints

Despite gaining popularity and use in various industries the higher olefin production face obstacles. Fluctuations in the prices of crude oil are the primary impact on the production expenses of higher olefins. Additionally, the traditional cracking procedure gives rise to impact on environmental issues. Stringent regulations and the emphasis on sustainability could result in a delay in the production process or necessitate the implementation of more nature-friendly technologies to reduce the environmental side effects.

Emerging opportunities and innovations

The potential for continued growth in the higher olefins industry is expanding. Indeed, from the point of gas shale, better-cracking technology like “M- Cracker”, which is driven both by cost-effectiveness and environmental sustainability might lead to bigger yields. The implementation of sustainable technologies, like microwave drying for naphtha cracking, is increasing and this is a great way for energy saving and waste disposal. For the promising scenario ahead, exploration through bio-based feedstocks with a renewable origin makes clear that greener means for higher olefins are better for various sectors that necessarily depend on these higher olefins.

Key Developments

- In June 2023: Orlen the renowned company from Poland is investing in the field of bioplastics. With a substantial amount of 25 billion Polish zloty, they are set to expand their olefins complex, with the primary objective of production of petrochemical products that are the crucial components to build for bioplastics.

- In October 2023: New PTFE- Free Lubrione the new formula offered by Avients this innovative solution achieves remarkable durability and friction without the need for fluorinated substances.

Get in Touch

Interested in this topic? Contact our analysts for more details.

Latest Thought Articles

Top OSAT Companies Driving Semiconductor Assembly and Test Services Worldwide

Recently

EV Charging Stations Market Outlook: Smart Charging, Fast Charging, and Regional Expansion

Recently

Future of Corporate Wellness: Global Trends and Regional Outlook

Recently

Regional Breakdown of the Mechanical Keyboard Market: Who Leads and Why?

Recently