Report Overview

Antimony Smelting Market - Highlights

Antimony Smelting Market Size:

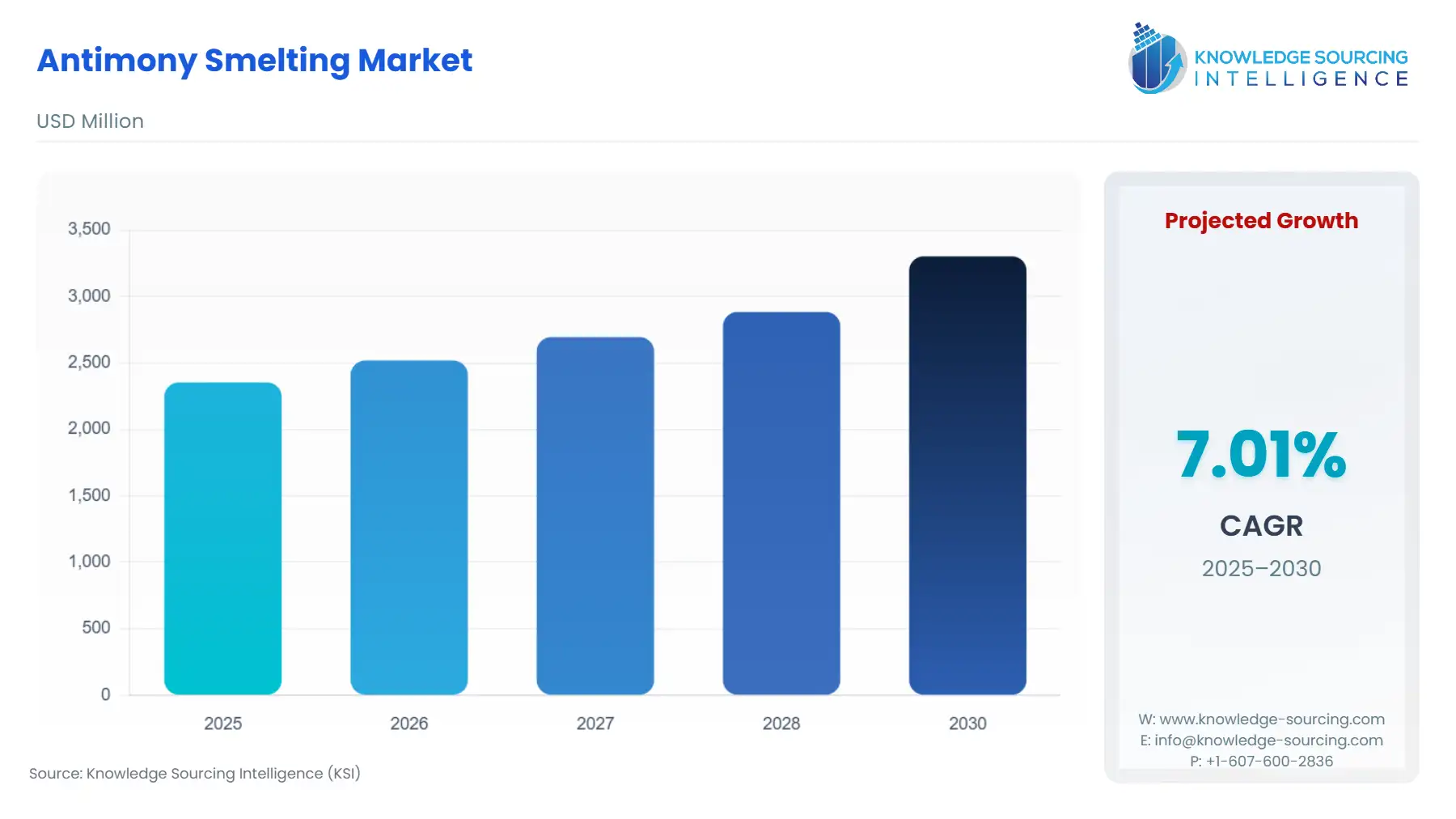

The Antimony Smelting Market is expected to rise at a CAGR of 7.01%, reaching USD 3.303 billion in 2030 from USD 2.354 billion in 2025.

The global antimony smelting market is experiencing steady growth due to increasing industrial demand from a variety of sectors. Antimony is a necessary raw material for the production of flame retardants, lead-acid batteries, alloys and specialty chemicals, which means that smelting operations are an integral part of the production of high-purity compounds for downstream applications. Increasing demand from the electronics, automotive, construction and chemicals industries promotes the need for efficient smelting solutions that can provide repeatable quality and adhere to regulatory requirements. Technological enhancements in smelting processes (including both pyrometallurgical and hydrometallurgical processes) improve efficiencies, reduce power consumption and provide better purity of final products. Companies are investing in modern capacity, coupled with greater automation in operations, both objectives enhancing productivity and satisfy the growing industrial demand.Environmental and regulatory standards are also influencing the market, resulting in smelters adopting cleaner technologies and sustainable applications. This tendency leads to meeting emission norms and a reduced environmental footprint whilst maintaining productivity.

Antimony Smelting Market Overview & Scope:

The antimony Smelting Market is segmented by:

- Type: The market is segmented into Antimony Ore, Antimony Trioxide, Antimony Alloys, and Others. Antimony Trioxide is the most commonly used, mainly in elements like flame retardants in plastics and textiles. Trioxide is also critical in battery applications and electronics. Antimony ore is mined from where it is then processed into the form of trioxide to meet the requirements of a large-scale industry. Antimony trioxide is in demand by safety standards that are a requirement in industries, through specifications in areas of construction to avoid things being flammable, especially in electronics. The production of trioxide involves roasting of ore; the processing route is key for trioxide end users, with a significant focus on efficiencies and product purity.

- Application: The market segment consists of Flame Retardants, Lead-Acid Batteries, Semiconductors, Solar Panels, and others. The market segment includes Flame Retardants, Lead-Acid Batteries, Semiconductors, Solar Panels, and others. Flame retardants are the largest application of antimony. Antimony trioxide is mixed with halogenated compounds to increase the fire resistance of plastics, textiles, and coatings. This is important in electronic applications, building products, and automotive components when they are required to meet safety requirements. Antimony is valued as an efficient fire retardant because of the characteristics it offers, such as durability, thermal stability, and fire inhibition. An increase in regulatory focus on fire safety in consumer products globally is pushing flame retardants, resulting in the flame retardants sector being at a steady level of high demand in the antimony market.

- Smelting Method: The market is segmented as pyrometallurgical and hydrometallurgical smelting. Pyrometallurgical smelting predominates, since it can extract the antimony from the ores at very high temperatures and yield the metal and oxide forms, which are suited for industrial use. This allows for large production, high recovery, and the smelting of ores of various grades. The companies engaging in pyrometallurgical processing are in a position to provide a uniform output, to compete in the market, and to meet the increasing demand from the metals processing downstream industries.

- Region: Geographically, the market is expanding at varying rates depending on the location.

________________________________________

Top Trends Shaping the Antimony Smelting Market

- Adoption of Advanced Smelting Technologies

More smelters are modernising pyrometallurgical and hydrometallurgical technology in an effort to achieve energy efficiency, maximum recovery of the metal in the ores and a higher grade and purity of the antimony produced. These advancements in technology are thus a means of availing to the industrial market the increased demand for metals and compliance with regulatory requirements, and contribute to reducing the environmental impact and operating cost of products throughout the supply chain.

- Focus on Sustainable and Eco-Friendly Operations

Increased regulation of environmental matters and enhanced general environmental goals of various companies are pushing the companies into adopting cleaner technologies and practices in relation to smelting, including emission control systems and waste recycling. This trend thus has implications of universal environmental compliance, incentives to reduce carbon footprints and increased attractiveness of the market to the downstream industries concerned with environmental issues.

________________________________________

Antimony Smelting Market Growth Drivers vs. Challenges:

Drivers:

- Rising Industrial Demand Across Key Sectors: The antimony smelting market is dominated by increasing demand from electronics, automotive, construction, and chemical industries. Antimony in the form of flame retardants, lead-acid batteries and alloys, in particular, require antimony of a quality suitable for the smelting operation. The growth of these industries will result in a growing need for processed antimony, leading to investments in increased capacity and new technologies. Smelters will be looking to produce quality products so as to meet the exacting standards sought in modern industry, ensuring reliability and safety. This forward trend is enhanced by the increasing pressure of fire regulations and product regulations, which we believe places smelting operations as the pivot of the industrial supply chain, assuring continued long-term growth in the market.

- Technological Advancements in Smelting Processes: Smelters are recognising the merits of using pyrometallurgical techniques and hydrometallurgical techniques and are increasingly developing such methods for use in the recovery of antimony. The application of new techniques will increase recovery of the lower ores, increase energy efficiency and end up with a high purity antimony. These recoveries in turn allow the new smelting operations to manufacture various products for flame agents, for alloying, for chemical creations, etc. New techniques will also enable the companies producing antimony to comply with modern safety and environmental regulations and enable their operations to remain competitive. The introduction of automation, rationalisation, etc., into smelting operations will increase productivity, which again will keep the supply of the product known as antimony in a healthy condition in relation to the anticipated growth in the industrial demands for antimony in the globe and thus give much larger scope for market growth and profitability.

Challenges:

- Environmental and Health Risks: Strict environmental regulations on emissions and waste management increase operational costs and complicate the establishment of new smelting facilities.

________________________________________

Antimony Smelting Market Regional Analysis:

- Asia-Pacific: The growing antimony smelting market in the Asia-Pacific region is due to the availability of large antimony reserves and the major smelting companies in China. The region also has an established industrial base with high demand from the electronics, automotive, construction, and chemical industries. Smelting companies in the Asia-Pacific will continue adopting new pyrometallurgical and hydrometallurgical technology in order to increase recovery and produce high-purity antimony, while also having to meet stringent environmental regulations. These companies will increase their production capabilities in response to government actions stimulating mineral exploration and industrial production. The Asia-Pacific will remain a leading world supplier of antimony and antimony products because of expanding downstream technologies and new investments in smelting facilities.

________________________________________

Antimony Smelting Market Scope:

| Report Metric | Details |

|---|---|

| Total Market Size in 2026 | USD 2.354 billion |

| Total Market Size in 2031 | USD 3.303 billion |

| Growth Rate | 7.01% |

| Study Period | 2021 to 2031 |

| Historical Data | 2021 to 2024 |

| Base Year | 2025 |

| Forecast Period | 2026 – 2031 |

| Segmentation | Type, Application, Smelting Method, Geography |

| Geographical Segmentation | North America, South America, Europe, Middle East and Africa, Asia Pacific |

| Companies |

|

Antimony Smelting Market Segmentation:

- By Type

- Antimony Ore

- Antimony Trioxide

- Antimony Alloys

- Others

- By Application

- Flame Retardants

- Lead-Acid Batteries

- Semiconductors

- Solar Panels

- Others

- By Smelting Method

- Pyrometallurgical Smelting

- Hydrometallurgical Smelting

- By Geography

- North America

- United States

- Canada

- Mexico

- South America

- Brazil

- Argentina

- Others

- Europe

- United Kingdom

- Germany

- France

- Italy

- Others

- Middle East and Africa

- Saudi Arabia

- UAE

- Others

- Asia Pacific

- Japan

- China

- India

- South Korea

- Taiwan

- Others