Report Overview

Thermoform Packaging Market - Highlights

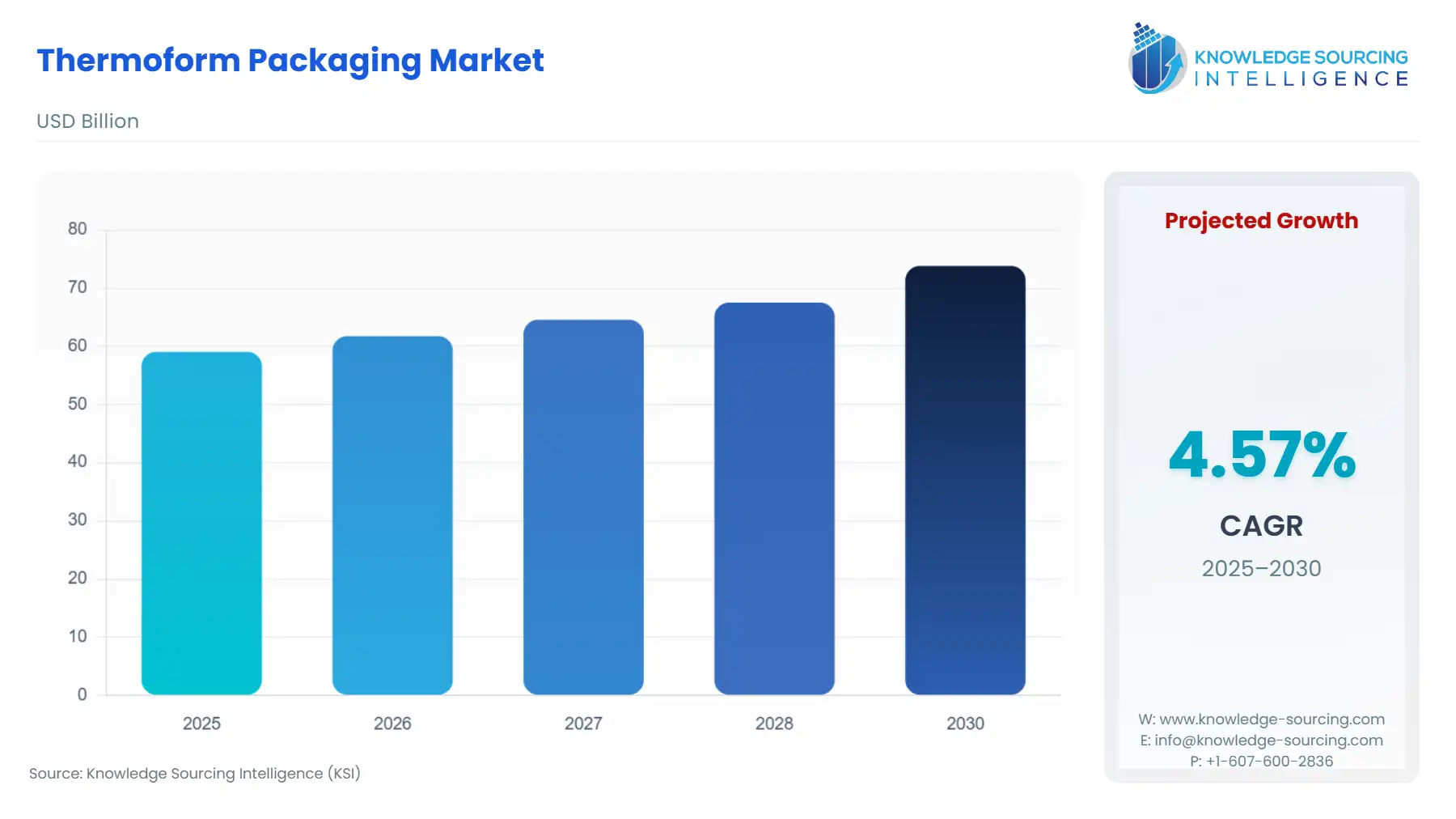

Thermoform Packaging Market Size:

The thermoform packaging market, with a 4.43% CAGR, is anticipated to reach USD 76.631 billion in 2031 from USD 59.072 billion in 2025.

Thermoform plastic packaging refers to a manufacturing process and packaging technique used to create custom-designed packaging solutions. It involves heating a thermoplastic sheet to a pliable temperature and then forming it into a specific shape using a mold or die. Once the material cools and hardens, it retains the desired shape and provides protective packaging for various products. Thermoform plastic packaging is used across various industries, including food and beverage, pharmaceuticals, electronics, cosmetics, and consumer goods.

Thermoform Packaging Market Trends:

The thermoform packaging market refers to the industry involved in the production and distribution of packaging solutions made from thermoformable plastic materials. Thermoform plastic packaging utilizes heat and pressure to shape thermoplastic sheets into various customized forms such as trays, containers, clamshells, and blister packs. This market is driven by factors such as the growing demand for visually appealing and cost-effective packaging, product protection requirements, customization options, and sustainability considerations. Thermoform plastic packaging finds applications across various industries, including food and beverage, pharmaceuticals, electronics, cosmetics, and consumer goods.

Thermoform Packaging Market Growth Drivers:

Product Protection:

Thermoform plastic packaging provides effective product protection from external factors such as moisture, dust, and physical damage. The sturdy and durable nature of thermoformed plastic offers a safeguard for delicate and perishable items during transportation and storage.

Customization and Versatility:

This packaging allows for high levels of customization and versatility. It can be tailored to specific product dimensions, shapes, and functionalities, including inserts, compartments, and windows. This flexibility meets the unique packaging requirements of various industries and products.

Cost-Effectiveness:

Thermoform plastic packaging is often considered a cost-effective solution. The manufacturing process can be efficient and streamlined, reducing production costs. Additionally, the lightweight nature of thermoformed plastic helps reduce transportation costs.

Sustainability and Recycling:

Increasing environmental consciousness is driving the demand for sustainable packaging solutions. Thermoform plastic packaging can utilize recyclable materials, and efforts are being made to improve the recycling rates of thermoformed plastic. This aligns with the market trend of reducing waste and environmental impact.

Product Visibility, Convenience and User-Friendly Design:

Thermoform plastic packaging often incorporates transparent or translucent options, allowing consumers to view the product inside without opening the package. This feature enhances the customer experience and builds trust in the product quality.:

It can be designed with features that enhance convenience for consumers. Easy-open mechanisms, resalable closures, and ergonomic designs contribute to user-friendliness and product usability.

Shelf Life Extension:

Thermoform plastic packaging can extend the shelf life of products by providing a protective barrier against moisture, oxygen, and other external factors. This feature is particularly valuable for perishable goods, helping to maintain product freshness and quality for longer periods.

Lightweight and Space-Efficient:

Thermoform plastic packaging is lightweight, contributing to reduced shipping costs and improved logistics efficiency. The compact design and stack-ability of thermoformed plastic containers optimize storage and shelf space, maximizing utilization.

Compliance with Safety Standards:

Thermoform plastic packaging can be designed to comply with safety standards and regulations specific to different industries. This ensures that products are packaged in a manner that meets the required safety, hygiene, and quality standards.

Positive growth in the food and beverage segment:

The segment that is experiencing positive growth in the thermoform packaging market is the food and beverage industry. This growth can be attributed to several factors. Firstly, the increasing demand for convenience foods and ready-to-eat meals has led to a surge in the need for lightweight, portable, and easy-to-use packaging solutions that provide product protection and maintain food freshness. Secondly, the rising popularity of online food delivery services and e-commerce has created a demand for packaging that can withstand the rigors of transportation while ensuring food safety. Additionally, the industry's focus on sustainability has prompted the adoption of recyclable and eco-friendly thermoform packaging materials, meeting consumer expectations for environmentally conscious packaging solutions.

Thermoform Packaging Market Players:

Amcor: Thermoform plastic packaging products by the company are recyclable and compostable plastic material that is made from plant-based materials. It is a good alternative to traditional plastics, as it can be recycled into new products or composted into soil. Amcor has launched several thermoformed plastic packaging products made from Eco-Flex, including clamshells for food products and trays for beverages.

Huhtamaki: Thermoformed packaging by the firm is a good alternative to traditional plastics, as it does not release harmful toxins into the environment when it breaks down.

Thermoform Packaging Market Geographical Outlook:

The North American region is expected to hold a significant share:

North America is expected to witness a steady CAGR in the thermoform packaging market. This can be attributed to several factors, including the region's well-established food and beverage industry, growing consumer demand for convenience packaging, and the presence of major players in the packaging sector. Additionally, the region's focus on sustainability and the adoption of eco-friendly packaging solutions align with the growing market trend. Furthermore, the increasing e-commerce activities and the need for robust packaging for online shipments further contribute to North America's market share in the thermoform packaging market.

Thermoform Packaging Market Key Developments:

In Feb 2023, Neste and ILLIG formed a strategic partnership to promote more sustainable solutions in thermoformed plastic packaging production through demonstration cases. The collaboration aims to validate the use of renewable and recycled materials in demanding applications by recreating value chains on a small scale.

In May 2022, MULTIVAC launched the R3 thermoforming packaging machine which is designed to run recyclable and environmentally friendly mono films, making it a sustainable option for food manufacturers. The R3 is also modular and easy to adapt to a wide range of customer requirements, making it a versatile and cost-effective choice.

List of Top Thermoform Packaging Companies:

Amcor Plc

Sonoco Products Company

DS Smith

Placon

Display Pack

Thermoform Packaging Market Scope:

| Report Metric | Details |

|---|---|

| Study Period | 2021 to 2031 |

| Historical Data | 2021 to 2024 |

| Base Year | 2025 |

| Forecast Period | 2026 – 2031 |

| Companies |

|

Report Metric | Details |

Thermoform Packaging Market Size in 2025 | USD 59.072 billion |

Thermoform Packaging Market Size in 2030 | USD 73.845 billion |

Growth Rate | CAGR of 4.57% |

Study Period | 2020 to 2030 |

Historical Data | 2020 to 2023 |

Base Year | 2024 |

Forecast Period | 2025 – 2030 |

Forecast Unit (Value) | USD Billion |

Segmentation |

|

Geographical Segmentation | North America, South America, Europe, Middle East and Africa, Asia Pacific |

List of Major Companies in Thermoform Packaging Market |

|

Customization Scope | Free report customization with purchase |

Thermoform Packaging Market Segmentation

By Material

Plastic

Paper

By Product Type

Blisters

Clamshells

Trays & Lids

Containers

By End-User

Food & Beverage

Pharmaceuticals

Personal Care & Cosmetics

Consumer Electronics

By Geography

North America

USA

Canada

Mexico

South America

Brazil

Argentina

Others

Europe

Germany

France

United Kingdom

Spain

Others

Middle East and Africa

Saudi Arabia

UAE

Others

Asia Pacific

China

India

Japan

South Korea

Indonesia

Thailand

Others