Report Overview

Global 3D Printer Market Highlights

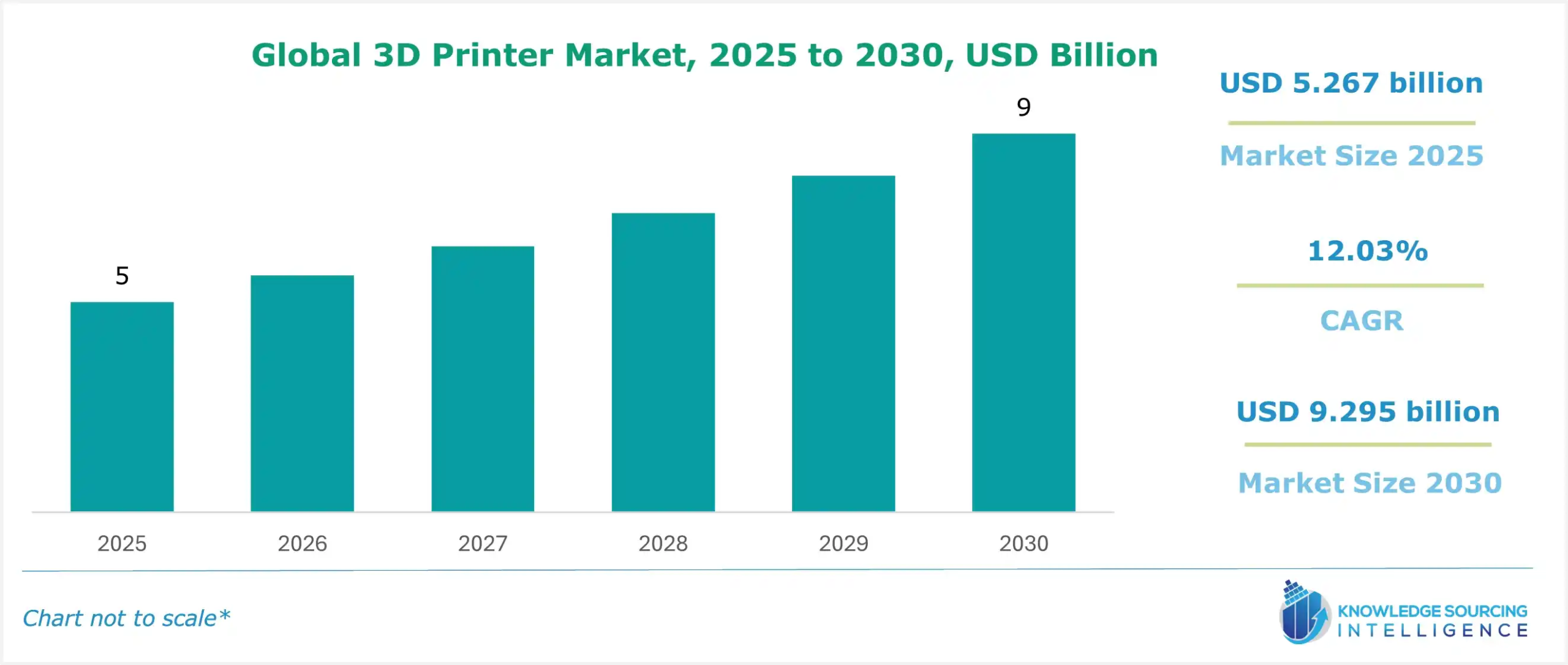

3D Printer Market Size:

The global 3D printer market is estimated to grow at a CAGR of 12.03% to attain US$9.295 billion in 2030, increasing from US$5.267 billion in 2025.

3D Printer Market Trends:

A 3D printer is a device that can manufacture products by a process known as additive manufacturing, in which a 3D object can be printed layer by layer through a digital 3D model that the user provides. These printers are mainly used by two audiences: higher-end industrial manufacturers and lower-end consumer craftsmen. 3D printers have started to appear in the automotive and aviation industry to produce parts requiring high accuracy levels. NASA has used 3D printing technology to create complicated component geometries. Furthermore, the expansion of the aerospace and defense industries is driving demand for 3D printing technology, which is expected to drive 3D printer market growth.

3D Printer Market Growth Opportunities:

- Increasing utilization of 3D printing technologies across multiple industries.

A major factor boosting the demand for 3D printers market globally is the increasing utilization of 3D printing technologies across multiple industries. 3D printing technology is among the most advanced and latest, transforming virtual projects or designs into reality. This technology offers multiple applications, especially in sectors requiring specialized manufacturing and casting expertise, like aerospace, automotive, manufacturing, and construction.

In the aerospace and defense industry, 3D printing technology offers key applications, from fabricating the outer body layer to developing engine parts. Several companies worldwide have developed new technologies to use 3D printing effectively in various industries. For instance, in May 2024, Agnikul, an Indian aerospace startup, successfully launched its first rocket, which included a fully 3D-printed engine.

Similarly, 3D printing technology also offers key applications in the construction industry. This technology can ensure an effective and faster construction process in this industry. Numerous companies and organizations have created new technologies and solutions, further boosting the use of 3D printing technology in the construction industry. In June 2024, COBOD International, a leading 3D printing solution and technology provider in construction, announced the construction of the first 3D-printed house in the Central Asian region. This house features the capability to withstand an earthquake with an intensity of 7 on the Richter scale.

- Growing prevalence in the prototyping market

3D printing uses materials, including plastics, resins, nylon, metals, etc. The cost of manufacturing products with these materials is cheaper compared to traditional manufacturing techniques. Most 3D printed products are also biodegradable and environment-friendly since they use materials acquired from natural substances.

3D printing prototypes, also known as Rapid Prototyping, help save manufacturers from wasting a ton of material since 3D printing technologies are much more accurate and can work error-free. The US Department of Defense is also using rapid prototyping to aid in efficiently testing and designing weapons and protective clothing. The US Reform Act mandates the use of competitive prototyping in large-scale defense procurement operations due to its inherent benefits. Rapid prototyping has also shown significant field success in detecting improvised explosive devices (IEDs). New technology developments are expected to boost the prototyping industry’s prominence as a tool in the toolkits of federal and defense commanders.

Because of the 3D printer’s cheap and accurate printing technique, they have been used in industries such as aircraft, automobile, aerospace, etc. Many companies such as Protolabs and 3ERP also help designers by 3D printing prototypes for them. This helps designers better understand their design flaws and properties.

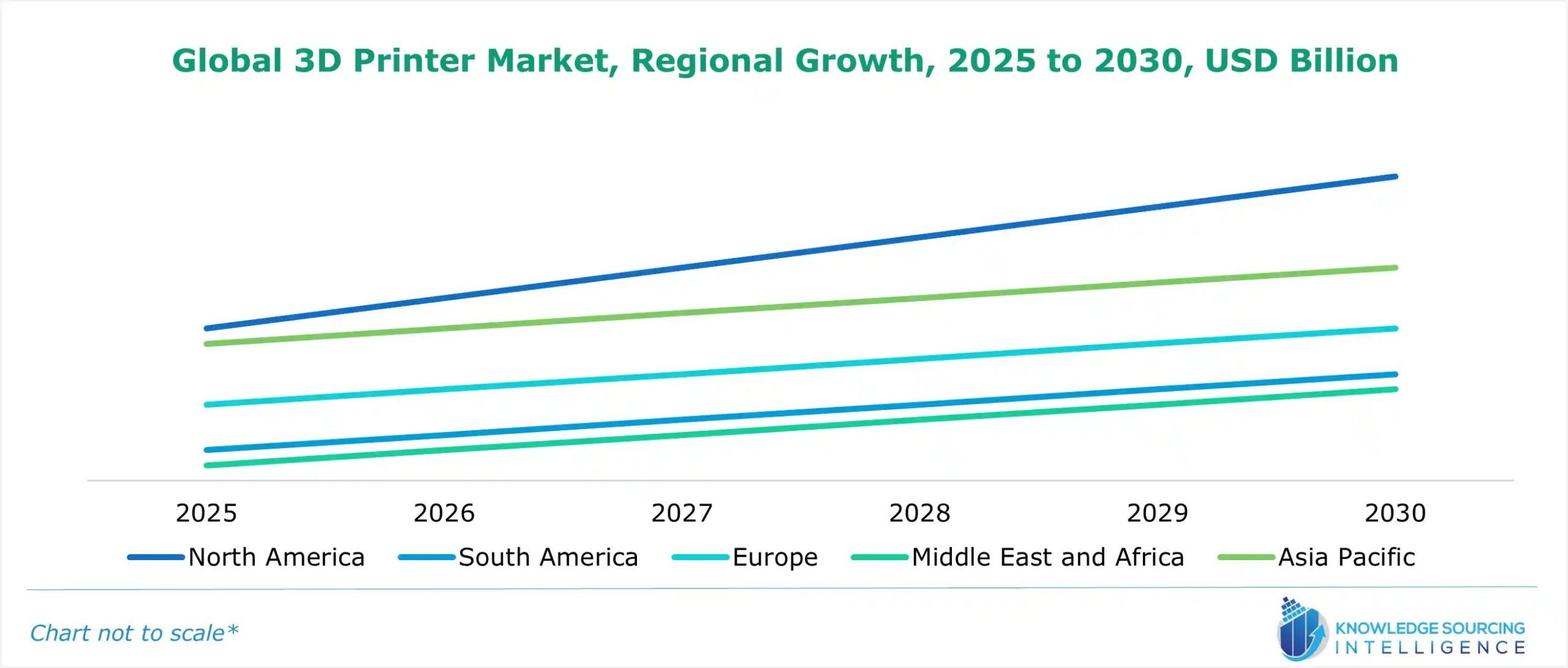

3D Printer Market Geographical Outlook:

- North America is forecasted to hold a major global 3D printer market share.

North America is expected to grow substantially in the 3D printing market, primarily due to the increased government support in this area. Since the customs duties on Electronically Transmitted Products in the US have been reduced to zero, the 3D printing market has become more affordable. The major companies in the 3D printing market include 3D Systems Corporation, Stratasys Ltd., the ExOne Company, etc., all of which are based in the US.

The US aeronautics and space industry has also been using 3D printing technology to produce and develop important hardware and equipment for research. SpaceX claims to have spent several years perfecting the 3D printing technology for flight equipment. Using direct metal laser sintering (DMLS) 3D printing technology, the team 3D printed a SuperDraco engine chamber constructed of Inconel, a high-performance superalloy. SpaceX sent its first 3D-printed rocket engine component on the Falcon 9 rocket for the THAICOM 6 mission.

In recent years, the US Department of Defense has also been employing technologies such as 3D print prototyping and platform modernization to aid in the efficient testing and design of weapons and protective clothing. Rapid prototyping has helped significantly in the success and detection of IEDs. Experts predict that future technical developments will elevate the 3D printer's prominence as an essential part of the development of defense equipment.

3D Printer Market Major Players and Products:

- HP Inc. is a multinational technological company based in the USA. The company offers a wide range of hardware and software solutions, including security, PCs, and printers, among others. In this market, the company offers various 3D printers and related solutions for multiple industries, such as education, aerospace, industrial, automotive, orthotics & prosthetics, and consumer goods.

- Bambu Lab is among the leading 3D printer manufacturers globally. The company offers various types of 3D printers and solutions, which include software like Bambu Handy & Bambu Studio. It also provides accessories and filaments for 3D printers, like hotends, anti-vibration feet, and AMS hubs. In the global 3D printer market, the company offers multiple categories of 3D printers, like the X1 series, P1 series, and A1 series.

3D Printer Market Key Developments:

- In April 2024, UltiMaker, a global 3D printing technology leader, launched its latest Factor 4, a new and state-of-the-art Industrial grade 3D printer designed to increase the efficiency of the manufacturing process globally. The new printer by the company offers end-to-end 3D printing solutions and has a temperature-controlled build volume of about 330x240x300 mm. This printer also features a uniform heating bed and ensures consistent performance.

3D Printer Market Scope:

| Report Metric | Details |

|---|---|

| Study Period | 2021 to 2031 |

| Historical Data | 2021 to 2024 |

| Base Year | 2025 |

| Forecast Period | 2026 – 2031 |

| Report Metric | Details |

| 3D Printer Market Size in 2025 | US$5.267 billion |

| 3D Printer Market Size in 2030 | US$9.295 billion |

| Growth Rate | CAGR of 12.03% |

| Study Period | 2020 to 2030 |

| Historical Data | 2020 to 2023 |

| Base Year | 2024 |

| Forecast Period | 2025 – 2030 |

| Forecast Unit (Value) | USD Billion |

| Segmentation |

|

| Geographical Segmentation | North America, South America, Europe, Middle East and Africa, Asia Pacific |

| List of Major Companies in 3D Printer Market |

|

| Customization Scope | Free report customization with purchase |

The global 3D printer market is analyzed into the following segments:

- By Component

- Hardware

- Software

- Services

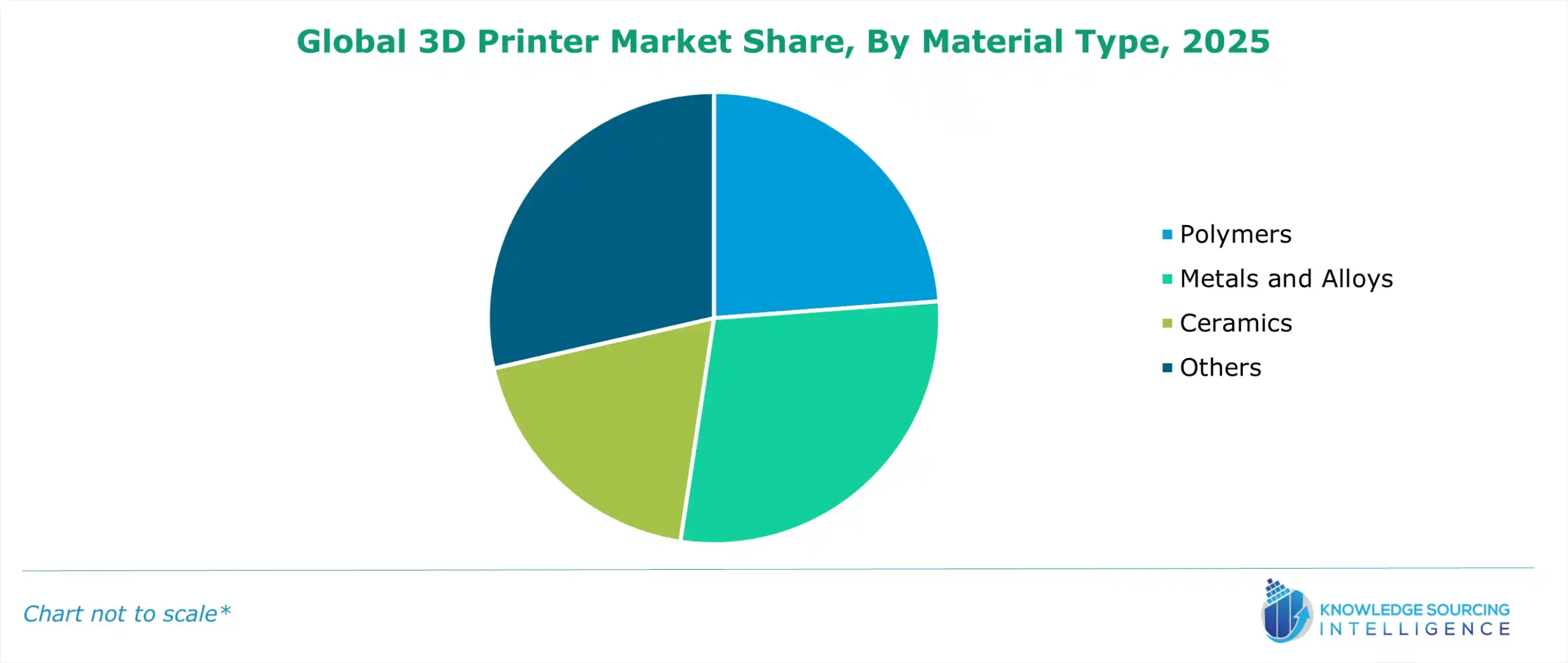

- By Material Type

- Polymers

- Metals and Alloys

- Ceramics

- Other

- By End-User

- Aerospace

- Medical

- Defense

- Automotive

- Other End Users

- By Application

- Functional Prototyping

- Tooling

- Educational Purpose

- By Technology

- CJP

- DMLS

- SLS

- MJ

- Others

- By Geography

- North America

- USA

- Canada

- Mexico

- South America

- Brazil

- Argentina

- Others

- Europe

- Germany

- France

- UK

- Others

- Middle East and Africa

- Saudi Arabia

- UAE

- Others

- Asia Pacific

- China

- India

- Japan

- South Korea

- Taiwan

- Thailand

- Indonesia

- Others

- North America