The Advanced Technological Features Fuel the Long-term Viability of Zinc Chemicals

Zinc, as a low-frequency element, is most often obtained by electrolyzing zinc sulfate. Apart from its own application, it is employed in the result of metal production and for coating. Zinc in metal form often goes into the production of nails galvanized as they have the attractive feature of a low melting temperature, and they can bind with iron or steel. To add to this, zinc is indeed an indispensable trace element in the human body. It is part of carbonic anhydrase and is contained in very high concentrations in red blood cells. Zinc as an element, is extremely important for many bodily functions like immune response, wound healing, blood clotting, thyroid activity, and others. Moreover, it is a key factor contributing to seeing and may even possess antiviral features.

Zinc is a very important specific element for humans, animals, plants, and microorganisms. It acts as the backbone of an array of industries - rubber vulcanization, paint, photocopy paper, chemicals, glass and ceramics, water and surface treatment, alloys, cosmetics, pharmaceuticals, plastics, inks, soaps, batteries, textiles, and electric equipment. Zinc oxide is a standard component of sunscreens and a protective element.

Global Production Trends

The zinc chemicals industry, which is gradually experiencing notable growth on major industrial levels, has several substantial driving forces. To be more particular, China is the number one producer in Asia, whose mine production rate in the year 2023 was 4000 mt. This favor in exploitation is due to the benefits as the raw materials are readily available at a cheaper price in the market.

For instance, according to the “International Lead and Zinc Study Group” published article in October 2023 it states that the production of purified zinc metal on a worldwide scale is anticipated to rise by 3.7% to arrive at 13.84 million tonnes in the year 2023. Furthermore, it is anticipated to rise by 3.3% to get to 14.30 million tonnes in the year 2024. The important propelling factor behind the surge will be the significant mine production in China with a predicted output rise of 6.7% in 2023 and 4.1% in 2024.

Zinc oxide is prepared on a large scale as a chemical zinc, which is widely used in paints, tires, sunscreens, and many other products too. The demand for it may increase due to the industry being expanding and people becoming more and more aware of the importance of protection from UV rays. On the other hand, zinc sulfate can function as a tiny fertilizer in agriculture as well as part of an animal feed supplement. Its elaboration is viewed as a positive one through the heavy consideration of upgrading agricultural yields and animal welfare.

Zinc Chemicals Use Cases

The zinc chemicals have several use cases that are enhancing their production and market around the globe. These use cases include agriculture, rubber manufacturing, painting and coating industry, ceramics, glass manufacturing, and pharmaceuticals are boosting the zinc chemicals in various industries, the growing importance towards zinc chemicals is due to increased urbanization and infrastructure developments are increasing the need for zinc chemicals proportionally as they have found in various paints, coatings, glass, and agriculture.

Zinc compounds ("salts") play a vital role in the production of an extensive array of our daily-use consumer products. None of the oxide pigments have such great importance as zinc oxide which is used in a variety of paints, coatings, and sunscreens due to its capability to block UV rays together with the bright white colour. On the other hand, zinc sulphate performs a vital function in plant nutrition by serving as a micronutrient fertilizer whether it is zinc which plants need for their healthy development. Another advantage of zinc is that zinc sulphate has zinc which will help in livestock feed supplements.

Furthermore, a combination of zinc oxide and ceramic is what results in a smooth finish. Consequently, zinc is involved in some flame-retardant plastics, too. Zinc is added not only to industrial products but also to personal care products. Often anti-dandruff shampoos and zinc pyrithione are incorporated into them which has antifungal properties.

For instance, according to the International Zinc Association published article in 2023, it states that zinc is one of the essential components in the expansion of the construction and infrastructure segment as the corrosion effect is mitigated and the shelf life of building materials is extended significantly. The protective nature of zinc adds up to 60% of total zinc consumption. It matters not whether the process is by galvanizing, applying thermal spray, or using zinc-rich paint.

Market Dynamics and Drivers

Various factors drive the zinc chemicals market, including increased construction activity and the global rise in automotive production. The rise of construction activity is coupled with paints and coatings and increased automotive demand globally is coordinated with components like tires and tubes. The rise in demand for these factors enhances the zinc chemicals market as zinc chemicals are the primary materials used in the production of products like paints, tires, and tubes.

One of the reasons why chemical consumption rises dramatically in the construction industry is the expansion of its development. Zinc and Oxide both of which are catalysts to the construction process achieve significant footfalls. The noticeable off-whiteness of concrete operates in professional productions of paint and cladding, whereas its durable nature provides structures with weather conditions, mainly rough weather conditions. Additionally, zinc which is a component of rubber is rubbed to give the mold in construction for the tires vehicles. The zinc-related industrial products consumption showing signs of boosting with the increase in urbanization and development of infrastructure systems. The various use cases in different industries propel the market for zinc chemicals.

The more manufacturers are producing cars, the higher levels of the zinc chemical production. Zinc is of great importance in ensuring good tune-up of vehicles. Zinc oxide, which is characterized by its versatility, will be used to enhance the wear and tear resistance of tires hence good performance, which is vital, especially in the age of fast automobile manufacturing. The boost in production of automobiles has seen the demand for these zinc-dependent products increase significantly, which has equally pushed the zinc chemicals market into the front.

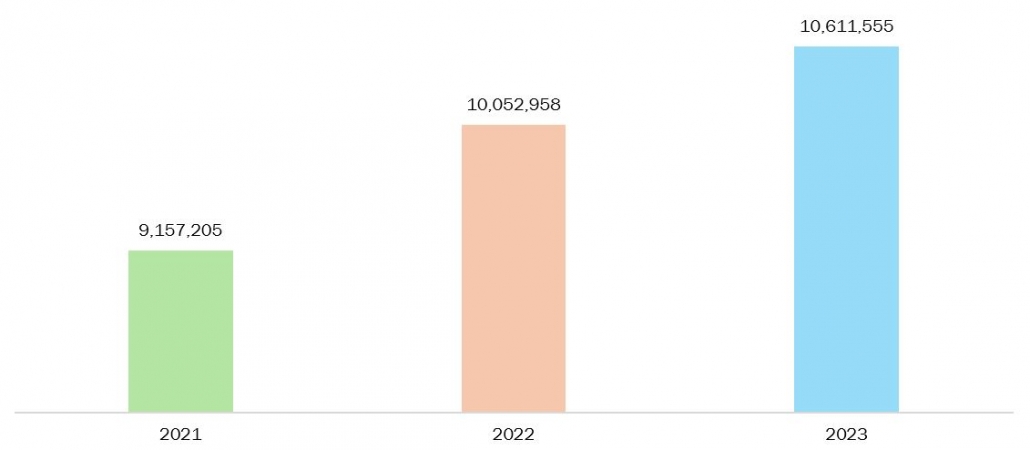

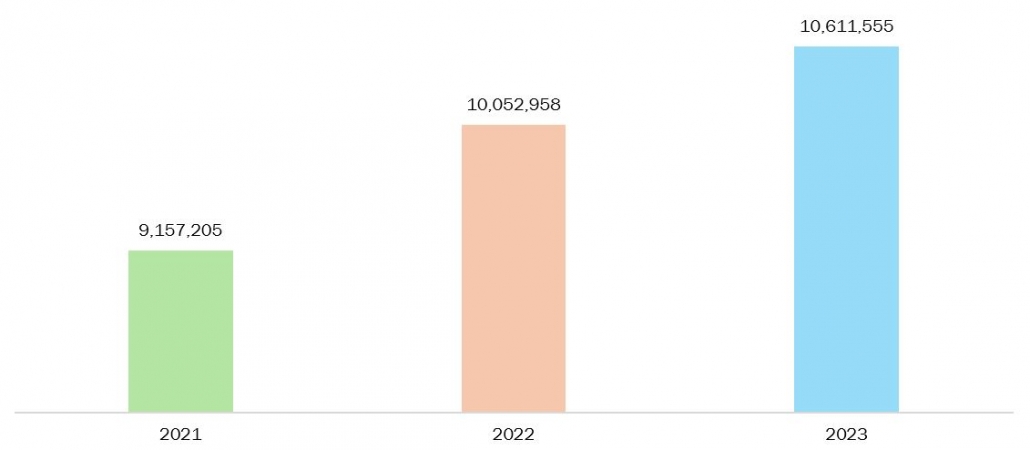

The zinc chemicals play a vital role in the production of various components of vehicles like tires and tubes with the rise in the vehicle production rate the growth for zinc chemicals will rise proportionally. For instance, according to the International Organization of Motor Vehicles Manufacturers published article in 2023 it states that the production of motor vehicles between the year 2023 with respective The United States in 10,611,555 units.

Figure 1: Vehicle Production in the USA Region (2021- 2023 in Units)

Source: The International Organization of Motor Vehicles Manufacturers (OICA)

Challenges and Constraints

Zinc substances production sector constantly faces a number of issues. The instability of zinc prices is the main limiting factor that can influence the overall cost of the manufacturing process as well as the profitability of manufacturers. Moreover, new environmental regulations with the notion of sustainability in mind could increase firms' production costs especially when they have to switch to ecological technologies. Additionally, titanium dioxide makes alternative materials of a specific sector, for instance, paints, can also be limited in the use of zinc chemicals. If the zinc chemical sector wants to retain its competitive edge then these challenges must be handled by incorporating cutting-edge technologies to it, by finding new sources for zinc production, and designing new applications of zinc.

Emerging opportunities and Innovations

The zinc chemicals industry comes up with not only fresh and unique ideas but also with new dynamics. There is a lot of research today for the improvement of the performance of what is already available. There is an interesting case of zinc oxide nanoparticles, which can be potentially applied for including self-cleaning coatings and antimicrobial surfaces in their properties. Furthermore, ongoing developments in recycling technologies have led to the emergence of the possibility of producing high-grade zinc from electronic waste, which could be another financially attractive and environmentally friendly alternative to conventional mining processes. Not only is the unique features of zinc being evaluated by researchers for its applications in energy storage and fire prevention but also new avenues are being explored in the market. Looking to disruptive innovations and brave these horizons, zinc chemicals industry will promote sustainable development and environmental protection.

Key Developments

Source: The International Organization of Motor Vehicles Manufacturers (OICA)

Challenges and Constraints

Zinc substances production sector constantly faces a number of issues. The instability of zinc prices is the main limiting factor that can influence the overall cost of the manufacturing process as well as the profitability of manufacturers. Moreover, new environmental regulations with the notion of sustainability in mind could increase firms' production costs especially when they have to switch to ecological technologies. Additionally, titanium dioxide makes alternative materials of a specific sector, for instance, paints, can also be limited in the use of zinc chemicals. If the zinc chemical sector wants to retain its competitive edge then these challenges must be handled by incorporating cutting-edge technologies to it, by finding new sources for zinc production, and designing new applications of zinc.

Emerging opportunities and Innovations

The zinc chemicals industry comes up with not only fresh and unique ideas but also with new dynamics. There is a lot of research today for the improvement of the performance of what is already available. There is an interesting case of zinc oxide nanoparticles, which can be potentially applied for including self-cleaning coatings and antimicrobial surfaces in their properties. Furthermore, ongoing developments in recycling technologies have led to the emergence of the possibility of producing high-grade zinc from electronic waste, which could be another financially attractive and environmentally friendly alternative to conventional mining processes. Not only is the unique features of zinc being evaluated by researchers for its applications in energy storage and fire prevention but also new avenues are being explored in the market. Looking to disruptive innovations and brave these horizons, zinc chemicals industry will promote sustainable development and environmental protection.

Key Developments

Source: The International Organization of Motor Vehicles Manufacturers (OICA)

Challenges and Constraints

Zinc substances production sector constantly faces a number of issues. The instability of zinc prices is the main limiting factor that can influence the overall cost of the manufacturing process as well as the profitability of manufacturers. Moreover, new environmental regulations with the notion of sustainability in mind could increase firms' production costs especially when they have to switch to ecological technologies. Additionally, titanium dioxide makes alternative materials of a specific sector, for instance, paints, can also be limited in the use of zinc chemicals. If the zinc chemical sector wants to retain its competitive edge then these challenges must be handled by incorporating cutting-edge technologies to it, by finding new sources for zinc production, and designing new applications of zinc.

Emerging opportunities and Innovations

The zinc chemicals industry comes up with not only fresh and unique ideas but also with new dynamics. There is a lot of research today for the improvement of the performance of what is already available. There is an interesting case of zinc oxide nanoparticles, which can be potentially applied for including self-cleaning coatings and antimicrobial surfaces in their properties. Furthermore, ongoing developments in recycling technologies have led to the emergence of the possibility of producing high-grade zinc from electronic waste, which could be another financially attractive and environmentally friendly alternative to conventional mining processes. Not only is the unique features of zinc being evaluated by researchers for its applications in energy storage and fire prevention but also new avenues are being explored in the market. Looking to disruptive innovations and brave these horizons, zinc chemicals industry will promote sustainable development and environmental protection.

Key Developments

Source: The International Organization of Motor Vehicles Manufacturers (OICA)

Challenges and Constraints

Zinc substances production sector constantly faces a number of issues. The instability of zinc prices is the main limiting factor that can influence the overall cost of the manufacturing process as well as the profitability of manufacturers. Moreover, new environmental regulations with the notion of sustainability in mind could increase firms' production costs especially when they have to switch to ecological technologies. Additionally, titanium dioxide makes alternative materials of a specific sector, for instance, paints, can also be limited in the use of zinc chemicals. If the zinc chemical sector wants to retain its competitive edge then these challenges must be handled by incorporating cutting-edge technologies to it, by finding new sources for zinc production, and designing new applications of zinc.

Emerging opportunities and Innovations

The zinc chemicals industry comes up with not only fresh and unique ideas but also with new dynamics. There is a lot of research today for the improvement of the performance of what is already available. There is an interesting case of zinc oxide nanoparticles, which can be potentially applied for including self-cleaning coatings and antimicrobial surfaces in their properties. Furthermore, ongoing developments in recycling technologies have led to the emergence of the possibility of producing high-grade zinc from electronic waste, which could be another financially attractive and environmentally friendly alternative to conventional mining processes. Not only is the unique features of zinc being evaluated by researchers for its applications in energy storage and fire prevention but also new avenues are being explored in the market. Looking to disruptive innovations and brave these horizons, zinc chemicals industry will promote sustainable development and environmental protection.

Key Developments

- In January 2024: Piramal Pharma launched a product called “Zinc Sulphate Concentration” the concentration is used as an intravenous injection. This injection is designed for pediatric patients with a decreased amount of dosage who weigh under 26 pounds.

| Subscribe Us |

Get in Touch

Interested in this topic? Contact our analysts for more details.

Latest Thought Articles

Top OSAT Companies Driving Semiconductor Assembly and Test Services Worldwide

Recently

EV Charging Stations Market Outlook: Smart Charging, Fast Charging, and Regional Expansion

Recently

Future of Corporate Wellness: Global Trends and Regional Outlook

Recently

Regional Breakdown of the Mechanical Keyboard Market: Who Leads and Why?

Recently