Report Overview

Advanced Recycling Market - Highlights

Advanced Recycling Market Size:

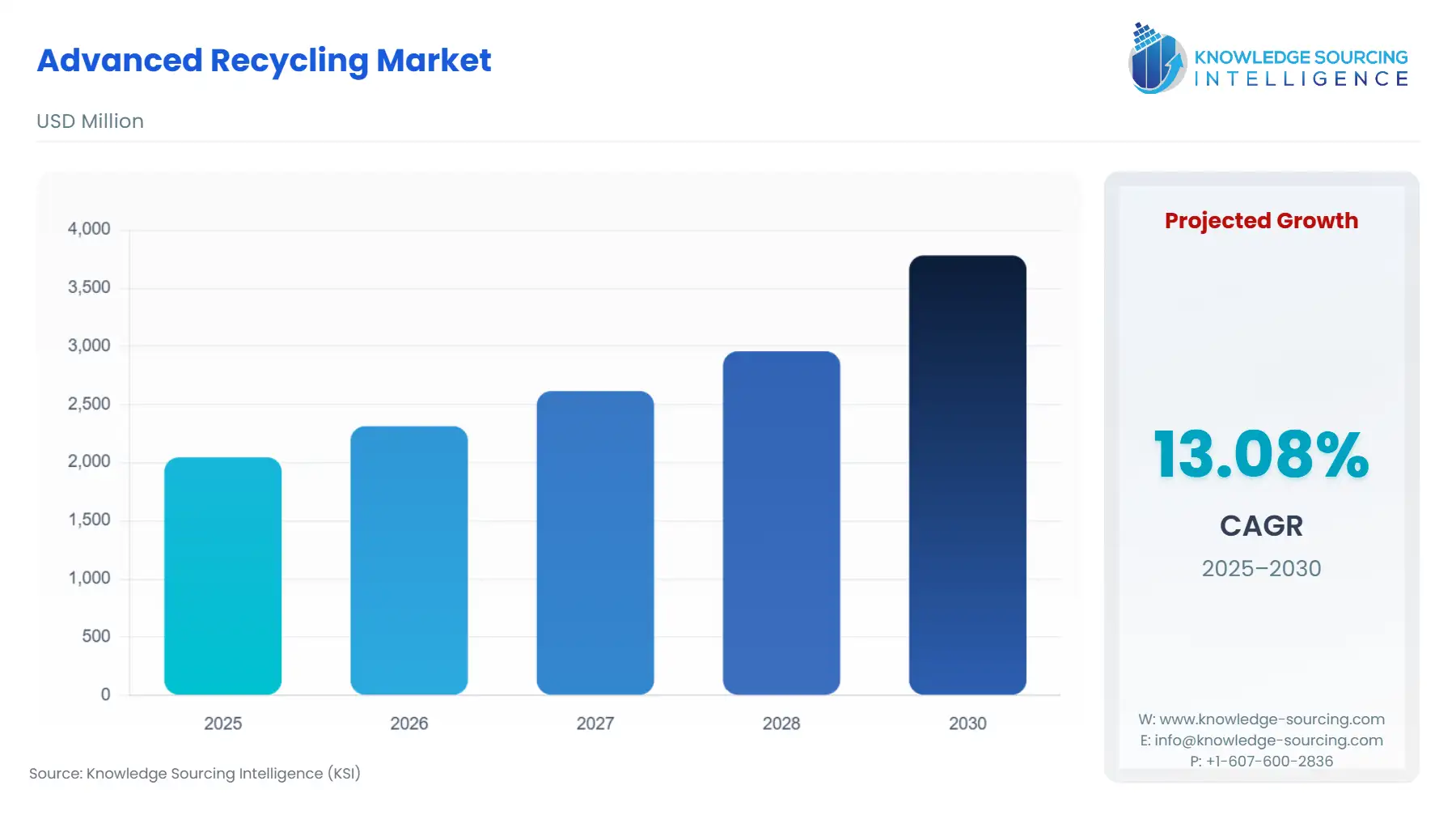

The advanced recycling market is set to witness robust growth at a CAGR of 13.08% during the forecast period, to reach USD 3.783 billion in 2030 from USD 2.046 billion in 2025.

Advanced Recycling Market Overview:

The advanced recycling market is pivotal in advancing the circular plastics economy, transforming post-consumer recycled (PCR) plastics into virgin-like plastics for high-quality applications. Sustainable plastic solutions leverage chemical and mechanical processes to enhance waste valorization, converting plastic waste into valuable resources. Decarbonization and recycling reduce emissions through energy-efficient technologies, aligning with global sustainability goals. This market supports industries like packaging, automotive, and electronics by providing scalable, eco-friendly alternatives to virgin plastics. The market drives innovation, sustainability, and resource efficiency in global plastic supply chains.

Advanced Recycling Market Trends:

The advanced recycling market is advancing, with the chemical recycling market gaining traction through innovative processes like pyrolysis plastic recycling, depolymerization recycling, and enzymatic plastic recycling. Solvolysis plastics and hydrothermal plastic recycling enhance material recovery, producing high-quality outputs. Gasification of plastic waste and plastic-to-oil technologies convert waste into valuable fuels, while plastic-to-monomer processes support molecular recycling for virgin-like plastics. These methods improve scalability and reduce environmental impact, aligning with circular economy goals. The focus on efficient, low-emission technologies drives adoption in the packaging and automotive sectors, positioning advanced recycling as a cornerstone for sustainable plastic waste management and resource recovery.

The market for advanced recycling has shifted due to improving mechanical and chemical recycling technology, utilizing modern-day processes such as gasification and pyrolysis. Key players are taking advantage of governmental policies and substantial market sizes to urge people to use recycled materials. Rising public awareness and stringent regulatory mandates build massive possibilities for advanced recycling. The United States and Asia implement sustainable action plans to drive technological advancements, potentially benefiting Europe and North America. Encouragement to innovate can quickly materialize with incentives and sustainability goals, more so around recycling.

Advanced Recycling Market Growth Drivers:

- Regulatory Push Is Driving Growth: Governments worldwide are implementing strict regulations to tackle waste reduction. Adopting EPR targets and developing advanced recycling technologies are two other ways to boost advanced recycling. In 2024, the Indian government issued new National Guidelines aiming at addressing plastic pollution, the Plastic Waste Management Rules, 2016, and it came up with new standards for these decrees. These guidelines bring in new regulations about extended producer responsibility, labeling biodegradable plastics, and reporting requirements. Hence, the EPR targets will be achieved effectively, with increased recycling performances ranging from 50-80% for individual categories.

- Advancements in Recycling Technology: Technological innovations in advanced recycling technology, such as pyrolysis/cracking and depolymerization, are developing efficiently. These innovations enhance processing efficiency, providing great scaling possibilities and ample cost reduction for packaging these technologies. These developments represent innovative solutions to the global plastic waste challenge and sustainability goals, particularly by reducing the reliance on virgin materials through recycling.

Advanced Recycling Market Segmentation Analysis by Technology:

- Pyrolysis/Cracking: Pyrolysis and cracking technologies convert plastic waste into valuable feedstocks like oils and gases. Investments in these techniques are expected to rise as they offer high efficiency for processing mixed plastics and producing high-quality feedstocks for use in the chemical industry.

- Gasification: It converts plastic waste into syngas, a mixture of gases that can be used either for power generation or chemical production. The technology is gaining steam, with tendencies toward better efficiency and scalability, making it the ideal solution for large-scale waste-to-energy operations.

- Others: Other technologies comprise depolymerization, which is breaking down plastics into monomers for creating new products from them. This technology is gaining popularity, showing better cost-effectiveness and higher purity outputs, thus enabling high-quality plastics and chemical production from waste in a sustainable manner. Another process is microwave-assisted recycling, which uses microwave radiation to break down plastics into recyclable components. It is one of the most promising solutions for more efficient and energy-saving recycling processes, with growing investments focused on enhancing its scalability and market adoption.

Advanced Recycling Market Segmentation Analysis by Product:

- Naphtha: One of the major by-products of chemical recycling, naphtha is used for producing high-quality petrochemicals and plastics. As an intermediate feedstock, it helps contribute toward a circular economy by reducing reliance on virgin material and enabling new plastic products to be formed from waste.

- Polymers: Polymers produced from plastic waste by advanced recycling technologies, such as pyrolysis, could be used to produce end-products used in construction, automotive, and other industrial sectors.

Advanced Recycling Market Geographical Outlook:

The Advanced Recycling market report analyzes growth factors across the following five regions:

- North America: The advanced recycling market is driven by regulatory incentives, corporate sustainability initiatives, and large investments in advanced recycling technologies such as pyrolysis. Major areas of concentration include reducing landfill reliance and high-quality feedstock production for the chemical industry.

- South America: Growth is slower but progressive, driven by increased environmental awareness and government-backed initiatives on waste management. The market concentrates on the small-scale adoption of chemical recycling technologies and solutions to increasing urban plastic waste.

- Europe: Strict environmental regulations and high commitment to the circular economy drive market expansion. Europe has the most advanced recycling industry, with leading adoption rates for cutting-edge technologies such as depolymerization and developments in large-scale recycling infrastructure.

- Middle East and Africa: The market is growing slowly. Investments in the region are being made in gasification and waste-to-energy technology. High plastic waste generation and efforts at management are underway, along with the infrastructure needed to support the circular economy.

- Asia-Pacific: The region is one of the fastest-growing regions based on industrialization, urbanization, and high plastic waste generation. Investments have been targeted toward scalable technologies like pyrolysis and expanding recycling infrastructure, with strong government and corporate participation driven by growing environmental concerns.

List of Top Advanced Recycling Companies:

- Plastic Energy

- Total Energies

- GARBO SRL

- Brightmark

- Synova

The major players in the advanced recycling market are Plastic Energy, Total Energies, GARBO SRL, Brightmark, and Synova, driving innovation in technologies like pyrolysis, gasification, and depolymerization. These companies work for sustainability and scalability to solve the problem of global plastic waste through advanced recycling solutions.

Advanced Recycling Market Latest Developments:

- In January 2024, TotalEnergies and New Hope Energy demonstrated the production of circular polymers from plastic waste at its La Porte, Texas, polypropylene plant. Treated ISCC+ feedstock, after pyrolysis, is used in its production.

- In November 2024, ExxonMobil is investing more than $200 million to expand advanced recycling in Texas, with the goal of processing 1 billion pounds of plastic annually by 2027, supporting circular economy goals.

Advanced Recycling Market Scope:

| Report Metric | Details |

|---|---|

| Study Period | 2021 to 2031 |

| Historical Data | 2021 to 2024 |

| Base Year | 2025 |

| Forecast Period | 2026 – 2031 |

| Report Metric | Details |

| Advanced Recycling Market Size in 2025 | USD 2.046 billion |

| Advanced Recycling Market Size in 2030 | USD 3.783 billion |

| Growth Rate | CAGR of 13.08% |

| Study Period | 2020 to 2030 |

| Historical Data | 2020 to 2023 |

| Base Year | 2024 |

| Forecast Period | 2025 – 2030 |

| Forecast Unit (Value) | USD Billion |

| Segmentation |

|

| Geographical Segmentation | North America, South America, Europe, Middle East and Africa, Asia Pacific |

| List of Major Companies in the Advanced Recycling Market |

|

| Customization Scope | Free report customization with purchase |

Advanced Recycling Market is analyzed into the following segments:

- By Technology

- Pyrolysis/Cracking

- Gasification

- Others

- By Product Type

- Naphtha

- Polymers

- Monomers

- Others

- By End-User Industry

- Packaging

- Construction

- Electronics

- Automotive

- Others

- By Geography

- North America

- USA

- Canada

- Mexico

- South America

- Brazil

- Argentina

- Others

- Europe

- United Kingdom

- Germany

- France

- Spain

- Others

- Middle East and Africa

- Saudi Arabia

- UAE

- Others

- Asia Pacific

- China

- Japan

- India

- South Korea

- Taiwan

- Others

- North America

Our Best-Performing Industry Reports:

- Power And Control Cable Market

- Electrically Conductive Adhesives Market

- Electromechanical Relay Market

Navigation

- Advanced Recycling Market Size:

- Advanced Recycling Market Highlights:

- Advanced Recycling Market Overview:

- Advanced Recycling Market Trends:

- Advanced Recycling Market Growth Drivers:

- Advanced Recycling Market Segmentation Analysis by Technology:

- Advanced Recycling Market Segmentation Analysis by Product:

- Advanced Recycling Market Geographical Outlook:

- List of Top Advanced Recycling Companies:

- Advanced Recycling Market Latest Developments:

- Advanced Recycling Market Scope:

- Our Best-Performing Industry Reports:

Page last updated on: September 17, 2025